More efficient production with IIoT devices – the future of digital manufacturing

24. April 2025

The digitalisation of industry is progressing rapidly – and IIoT devices play a key role in this development. Learn which technologies are behind the Industrial Internet of Things, how they optimise your production processes, and what specific benefits they offer your business. The ultimate guide to greater efficiency through intelligent connectivity.

Are you wondering what the term IIoT actually means and how this technology can revolutionize your manufacturing operations? Many production managers are faced with the challenge of digitalizing their processes while simultaneously improving efficiency. The Industrial Internet of Things (IIoT) is a specialised sector within the broader Internet of Things (IoT) ecosystem, focusing on the connectivity of industrial machines and equipment. It offers tremendous potential – but only with the right understanding and a well-thought-out implementation strategy.

In this article, you’ll learn everything about IIoT devices and how to use them profitably in your production.

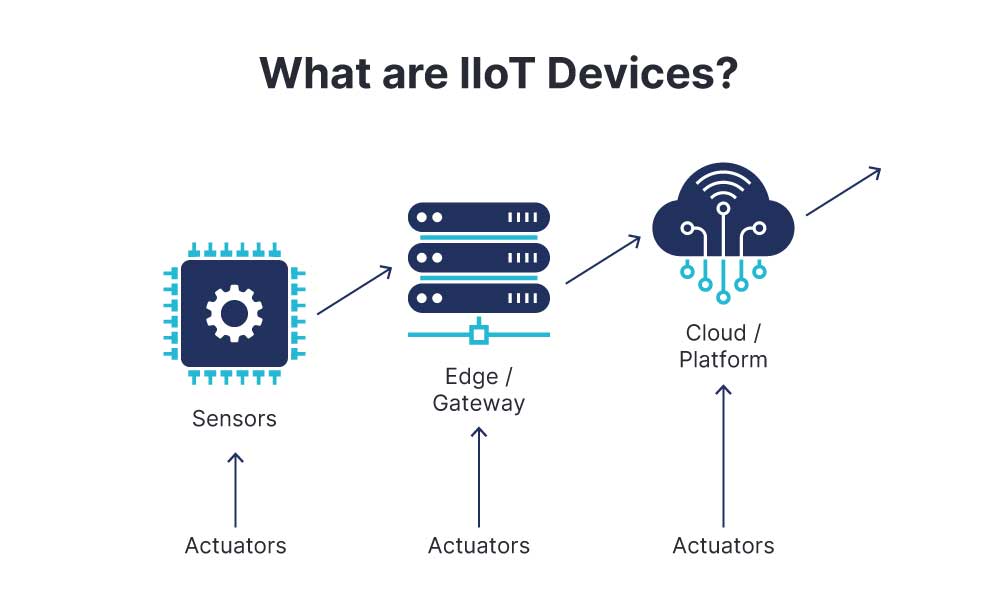

What are IIoT devices?

#IIoT (Industrial Internet of Things) devices are intelligent, networked components that collect, exchange and analyse data in industrial production environments. They form the foundation of digital manufacturing by connecting machines, sensors, controllers and software solutions in a shared network. The most important IIoT devices include sensors for measuring temperature, pressure, vibration or energy consumption, actuators for process control and edge gateways that process data directly at the machine. Retrofit modules, which digitally upgrade older systems, also play a crucial role in the gradual digitalisation of existing production lines. With their robust design, real-time capability and compatibility with common industrial protocols such as OPC UA or MQTT, IIoT devices are specially designed to meet the requirements of industrial production. They create transparency across all manufacturing processes, provide valuable real-time data for decision-making and thus lay the foundation for Industry 4.0 – and increasingly also for Industry 5.0.

With the Clouver IIoT platform from ProCom Automation, we intelligently network your machinery and optimise your processes for the long term. Discover potential for your optimisation!

The Revolution of Connected Manufacturing

IIoT devices are far more than just connected sensors. They form the backbone of modern manufacturing and enable a completely new way of production control. Unlike conventional IoT devices for consumers, IIoT components are specifically designed for industrial requirements. They operate reliably under the harshest conditions and provide precise data for your process optimisation.

In addition to high robustness and real-time capability, Artificial Intelligence is increasingly being used directly at the network edge (Edge AI). This enables important decisions to be made within milliseconds, without having to send data to the cloud first. This combination of edge computing and AI is one of the central trends in 2024 for minimising response times and enabling autonomous process control.

The integration of IIoT in your manufacturing creates a fully connected production environment. Every machine, every sensor, and every process becomes part of an intelligent network. The continuous collection and analysis of real-time data enables:

- Predictive maintenance through permanent condition monitoring

- Automatic process optimisation based on real-time data

- Increased product quality through constant parameter control

- Reduced scrap rates through early error detection

- Enhanced energy efficiency through optimised resource usage

- Support for sustainable production in line with Green IIoT: Intelligent systems help conserve resources, reduce emissions, and meet legal environmental requirements

Advantages of IIoT devices

The use of IIoT devices – also known as industrial IoT devices – offers manufacturing companies measurable advantages in all areas of production. The continuous collection and analysis of real-time data from networked industrial systems and IIoT sensors enables precise monitoring of performance indicators. This enables bottlenecks and malfunctions to be detected at an early stage, downtime to be reduced and overall equipment effectiveness (OEE) to be significantly improved. At the same time, intelligent IIoT devices enable predictive maintenance – a key factor in avoiding unplanned downtime and extending the service life of machines.

In addition, IIoT solutions increase transparency throughout the entire production process. Whether energy consumption, quality parameters or machine utilisation – all relevant data is available in real time and forms the basis for data-driven decisions. Companies that use IIoT in production benefit from greater efficiency, more flexible processes and significant cost reductions. Typical examples of IIoT devices include intelligent sensors for condition monitoring, edge gateways for local data processing and retrofit modules that digitise existing systems. In conjunction with platforms such as Clouver, this creates a fully networked manufacturing environment – the decisive step towards Industry 4.0 and Industry 5.0.

For more information on IIoT, see the article Industrial Internet of Things (IIoT): What is it?

Technological Foundations for Maximum Efficiency

The world of IIoT devices encompasses various technologies that work together seamlessly. Edge computing plays a central role here. This technology enables data processing directly at the source, i.e., at your machines and systems. This minimises response times and reduces network load.

Smart sensors form the basis for precise data acquisition. These intelligent sensors continuously monitor a wide range of parameters:

- Temperature and humidity

- Vibration and acceleration

- Pressure and flow

- Current and voltage values

- Position and movement

The recorded data is analysed using machine learning algorithms to detect patterns and identify anomalies early on. This makes it possible to predict machine faults before they lead to costly downtime.

In 2024, AI models running on edge devices (TinyML) are becoming increasingly important, as they enable powerful analysis and autonomous action even on resource-constrained hardware. In addition, the intelligent combination of various sensors (“sensor fusion”) is becoming standard practice to provide even more comprehensive insights into machine conditions.

Open frameworks such as EdgeX Foundry simplify the integration of various sensors and devices in heterogeneous environments.

Practical Implementation in Your Industrial Manufacturing

The integration of IIoT devices into existing production environments takes place step by step. A systematic approach is crucial for success:

1. Analysis of the Existing Infrastructure

- Assessment of current machines and equipment

- Identification of critical processes and optimisation potential

- Evaluation of IT infrastructure and network capacity

2. Development of a Tailored IIoT Strategy

- Definition of specific goals and KPIs

- Selection of suitable IIoT devices and technologies

- Creation of a detailed implementation plan

3. Step-by-Step Integration and Scaling

- Start with pilot projects in selected areas

- Continuous monitoring and optimisation

- Gradual expansion to other production areas

Practice shows: With the right strategy and professional support, IIoT integration can lead to significant improvements:

- Productivity increases of 20–30%

- Reduction of unplanned downtime by up to 50%

- Energy savings of 10–20%

- ROI within 12–24 months

Modern methods such as low-code and no-code platforms are gaining importance in 2024. They allow even small businesses without extensive IT teams to quickly and flexibly implement and adapt IIoT solutions. This makes digital transformation more accessible and faster for many companies. A particularly effective example of IIoT devices in practice is RFID integration in digital manufacturing, which enables automatic product identification and paperless workflows. This is particularly relevant for the integration of IIoT devices with existing CNC machines and other legacy equipment.

Security and Future Viability

Implementing IIoT devices requires a well-conceived security concept. The Clouver platform from ProCom Automation sets standards in this regard with:

- End-to-end encryption

- Multi-factor authentication

- Regular security updates

A modern security approach based on the “Zero Trust” model is becoming the industry standard in 2024. Here, no component is automatically trusted; instead, every access request is verified through multi-level checks. In addition, automated security monitoring and threat detection systems are being established to immediately report unusual behaviour.

The modular architecture ensures maximum future-proofing. New functions and technologies can be easily integrated so that your IIoT solution grows with your needs. Furthermore, sovereign European data spaces (e.g. GAIA-X) are gaining importance to ensure data security and data sovereignty in an international context.

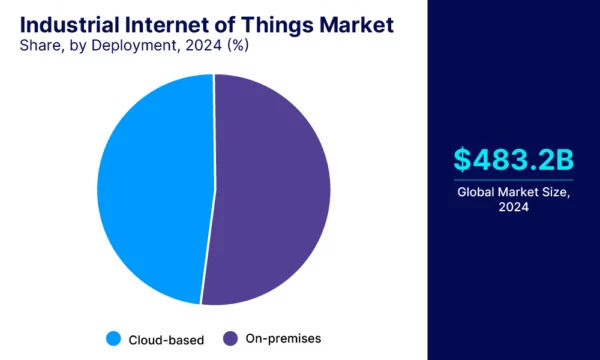

Market development and growth potential of IIoT technologies

The global market for the Industrial Internet of Things (IIoT) is growing dynamically, highlighting the increasing importance of networked industrial applications. With advancing digitalisation and the growing demand for real-time data for process optimisation, companies are investing more heavily in IIoT solutions. Recent studies by Grand View Research show that the IIoT market will experience strong growth in the coming years – as will the field of IoT end devices, which serve as central data suppliers in the industrial value chain.

The global market for the Industrial Internet of Things (IIoT) was estimated at USD 483.16 billion in 2024. (Source: Grand View Research, 2025)

The forecast predicts that the market will grow to USD 1,693.44 billion by 2030, with a compound annual growth rate (CAGR) of around 23.3% between 2025 and 2030. (Source: Grand View Research, 2025)

A supplementary study estimates the market for IoT devices to be worth USD 70.3 billion in 2024, with an expected growth to USD 181.17 billion by 2030 (CAGR ≈ 16.8%) (source: Grand View Research, 2025).

Conclusion: Industrial Internet of Things (IIoT) as the Key to Success

IIoT devices are more than a technological trend – they are the key to sustainable competitiveness in modern manufacturing. By intelligently connecting your production, you create the foundation for continuous optimisation and innovation.

New technologies such as Edge AI, Green IIoT with a focus on sustainability, Zero Trust security models, and flexible implementation approaches (low-code/no-code) ensure that your production is future-ready in 2024. With the right strategy and an experienced partner like ProCom Automation, your factory’s digital transformation is destined for success.

Further technical articles on the topic of IIoT

Industrial Internet of Things (IIoT): What is it?

Find out how the Industrial Internet of Things is laying the foundation for networked production processes.

IIoT tool monitoring: How to keep an eye on your production monitoring

How to use real-time data from IIoT devices to increase efficiency, transparency and plant availability.

Calculating OEE – Formula, benchmarks & tips for optimisation

Learn how to analyse and improve your overall equipment effectiveness (OEE) with the help of IIoT data.

Digital manufacturing with RFID: Automation and transparency for industry

Discover how Clouver, as an IIoT platform, is enabling the next level of industrial digitalisation.

FAQ

Which cost factors should companies consider when introducing IIoT devices?

Typical cost items include hardware (sensors, gateways), network infrastructure, integration effort, software licences as well as ongoing maintenance and updates. At the same time, reduced downtime, greater transparency and optimised processes often lead to a quick amortisation.

Which IIoT solutions are particularly suitable for small and medium-sized enterprises?

SMEs benefit from modular IIoT solutions and retrofit systems that make existing machines internet-capable. These tools enable a cost-efficient entry into the industrial Internet of Things.

Which qualifications do employees need in order to handle IIoT devices?

No in-depth IT knowledge is required for the use of IIoT devices. A basic understanding of data, machine processes and digital workflows is often sufficient. Training courses provide practical instruction on how dashboards are used, alarms are assessed and digital workflows are applied.

How can companies reliably assess the success of IIoT projects?

Success criteria include measurable improvements such as shorter reaction times, stable process flows, reduced maintenance costs or higher utilisation. In addition, companies can consider qualitative factors such as user acceptance or improved decision-making foundations.

Which organisational prerequisites need to be established for a successful IIoT project?

Clear responsibilities, a defined data strategy and the involvement of all relevant departments – from IT to production and quality management – are important. A step-by-step approach helps minimise technical and organisational risks.