Waterjet Cutting

ProCom Automation’s CNC control solution for waterjet cutting stands out with its intuitive and straightforward operation, even in complex applications. Numerous specific functions and adjustment parameters ensure flexibility and high cutting quality in waterjet cutting.

Optimised for use in your waterjet cutting machine

With ProCom Automation’s CNC control solution, you receive a solution that is precisely tailored to your waterjet cutting machine. In close collaboration, we address your specific requirements and develop a control solution that ensures precision and productivity for your machines.

Take advantage of our extensive experience and technical know-how in waterjet cutting.

Performance in Focus

By employing state-of-the-art technology and specific algorithms, you achieve a cutting process that excels in speed and precision. The precise control allows for accurate cutting, even in complex applications, while the intuitive user interface ensures effortless operation. Our CNC control solution for waterjet cutting handles a wide range of materials and thicknesses, making it the ideal choice for machine builders focusing on diverse applications in waterjet cutting.

The Control Solution's Highlights

- Applications with pure, abrasive, or suspension waterjet

- Waterjet-specific corner and radius treatment

- Alternative pierce-in methods and strategies

- Parametrisable abrasive dosing

- Dynamic kerf and bevel compensation

- Bevel cutting with freely definable angular transitions

- 3D cutting with five axes

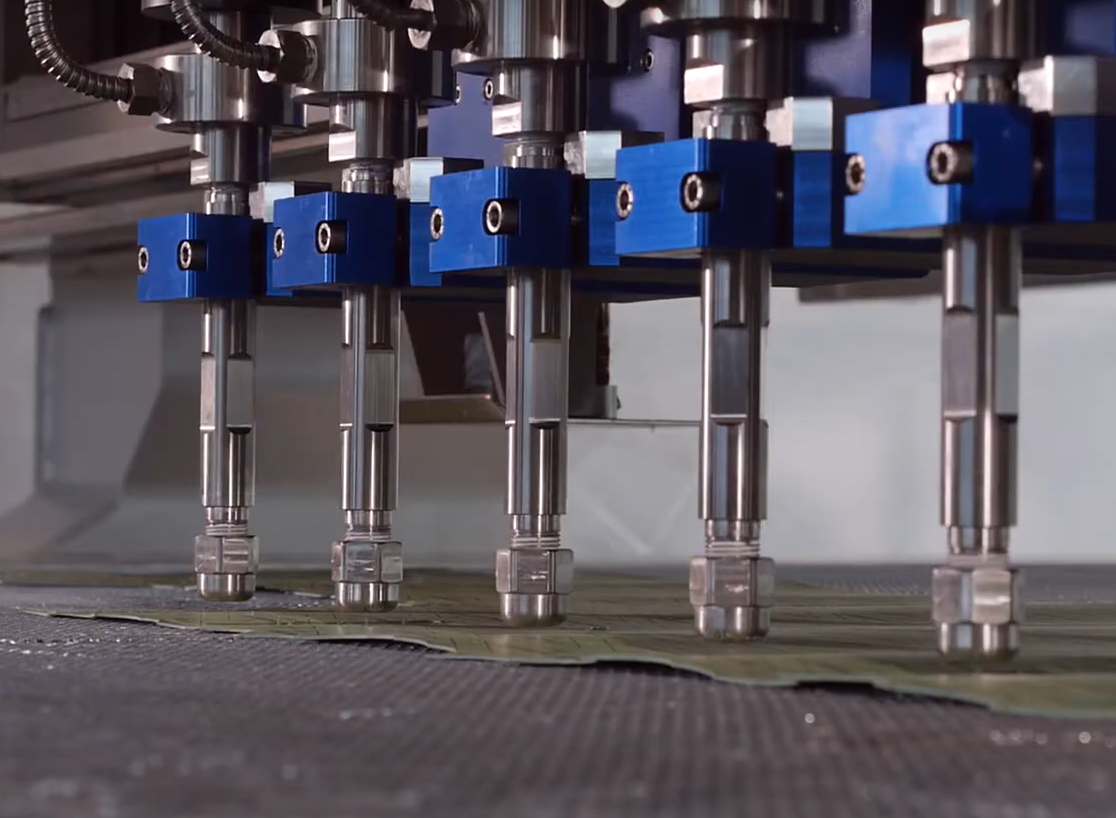

- Multi-head cutting (e.g. 6 cutting heads)

- Fully automated resuming on abort position

- Graphic-interactive start position determination

- Dry-run mode for accelerated test run without waterjet

- Support of 3rd party CAM tools

- Job order costing

- Dynamic jet-lag compensation

- OPC UA interface for capturing operational data and integrating your machine into production processes

Your Advantages as a Machine Builder

Choose ProCom Automation’s control solution and benefit from numerous valuable advantages:

Intelligent, Technology-Specific Motion Algorithms

For maximum performance of your cutting machines and precise cutting results at the highest level.

All-In-One Control Solution

CNC and CAM software, control hardware, and Drive Technology – get them all in one package or choose the component(s) you need.

Custom Functionality Adaptation

Custom development according to your wishes and requirements.

Fast Commissioning

Your machine with the ProCom Automation control solution is ready for operation in no time.

Professional Support

Reliable and personal support from our staff: on-site during commissioning as well as for all technical questions.

Personal Service

A personal contact for all concerns at any time – trust in the advice and support from our experts, along with guaranteed assistance for all technical inquiries.

Future-Oriented Development

Continuous optimisation of functions and motion algorithms based on current and future market requirements and customer needs.

Waterjet Cutting? How Does That Work?

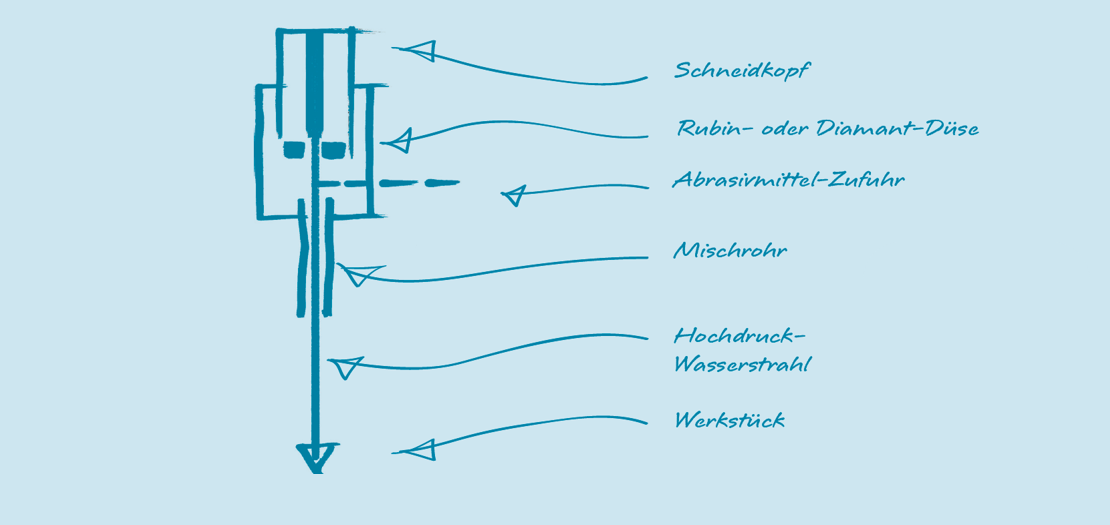

“Schneidkopf” = cutting head; “Rubin- oder Diamant-Düse” = ruby or diamond nozzle; “Abrasivmittel-Zufuhr” = abrasive supply; “Mischrohr” = mixing tube; “Hochdruck-Wasserstrahl” = high pressure waterjet; “Werkstück” = workpiece

A Short Explanation

Water is compressed by a high-pressure pump to up to 6000 bar and channelled through a nozzle into the mixing pipe. Optionally, abrasive agents are introduced into the tube.

Compressed under high pressure, water separates even hard and thick materials. Whether it is the hardest stone or soft foam, paper, wood, or food, high-strength steel, metals, or even non-ferrous metals – all of these can be cut with water. No heat is introduced into the material, and the additional step of deburring is eliminated.

In Action: Waterjet Cutting With the CNC300 Control Solution

Take a look at the CNC control solution in use at our customer:

Frequently Asked Questions

What does the complete solution package from ProCom Automation include?

As a ProCom Automation customer, you receive a complete solution package comprising the following components:

- CNC300PRO in the preferred configuration (i3, i5, or i7)

- CNC300 software solution package, consisting of ergoCNC® and ergoCAM® with the latest release version for textile cutting

- Drive Technology from leading manufacturers

- Interface to the IIoT production monitoring platform Clouver for analysing your machine data

The software solution for textile cutting (cutter software) is available in three variants: Essential package, Professional package, and Premium package, which you can choose based on your requirements. Feel free to contact our experts for further, comprehensive advice.

Can we retrieve the machine operating data?

Yes, the control solution captures a set of operational data, which, for example, can be made available through the IIoT production monitoring platform Clouver.

Is it possible to have individual functions programmed?

If a function you need is not already included in the standard features of our solution, we are happy to explore the possibility of individual function extensions. Feel free to contact our experts for comprehensive advice.

Is there a suitable CAM solution?

Naturally! The CAM solution from ProCom Automation is part of your complete solution package. The ergoCAM® software forms a unified system with the ergoCNC® software, ensuring a seamless transition between your work preparation and the cutting process. For more detailed information, consult our experts who will happily provide comprehensive advice.

Does ProCom Automation offer suitable drive technology?

Certainly! Suitable drive technology for the control solution is also part of your complete solution package. We have been working with leading manufacturers for many years, providing you with reliable and robust drive technology for smooth and precise movements.

How long does commissioning take?

Based on our experience, we estimate that initial commissioning of your machine in collaboration with your machine experts and our control experts, being pre-coordinated and well-prepared on both sides, can be successfully completed within 2-3 weeks at your facility.

What support do I receive during commissioning?

You will receive personal support from ProCom Automation experts on-site for the commissioning of the first pilot machine. This includes step-by-step checks of all motors, aggregates, sensors, and actuators, as well as the configuration and commissioning of their associated functions. Our experts on-site will perform the configuration and commissioning of all participants in the EtherCAT communication bus, the creation of the necessary complete EtherCAT configuration files, the required detailed parametrisation of all associated CNC parameters for the coordinated contour machining movements of all machine axes, as well as the control of all other tools and aggregates (vacuum control, extraction, material transport, etc.) for the pilot machine.

Our experts will accompany the fine-tuning and optimisation of the drive components and axis control loops, as well as the securing of the determined parameter files.

Additional serial machines will be set up and commissioned based on the parameter and configuration files created during the pilot machine project.

What are the prerequisites for serial production?

The CNC300PRO control solution is a mature and much-used solution in many facilities globally.

Once the necessary mechanical and electrical components, as well as the parametrisation and configuration of the CNC control, all I/O modules, and the drive components tailored to the respective machine, are set up and fine-tuned for a pilot machine, subsequent new machine installations will require only a minimal amount of time.

Additional serial machines will be set up and commissioned based on the parameter and configuration files created during the pilot machine project.

WANT TO LEARN MORE? REACH OUT TO AND CONNECT WITH US!

Simply choose your preferred time slot and book a free and non-binding conversation with our experts. In 30 minutes, you will receive:

- More detailed information about our control solution and its technology-specific features

- Insight into how we shape customer projects and collaboratively develop an individually optimised solution with our clients

- Answers to the questions you bring forward

- An initial assessment from our experts regarding potential collaboration

- A tailored, non-binding offer following the discussion, if desired

Further discover the variety of ProCom Automation Control Solutions

This might also be of interest to you

Yatai Ji

Key Account Manager

More Information? Reach Out to Us!

Learn more about our Clouver products and potential collaboration. Simply get in touch with us by phone or email. I look forward to a personal exchange!

- Phone: +49 241 93681-500

- Email: contact@procom-automation.de