How Can You Successfully Shape Digital Transformation in Your Production?

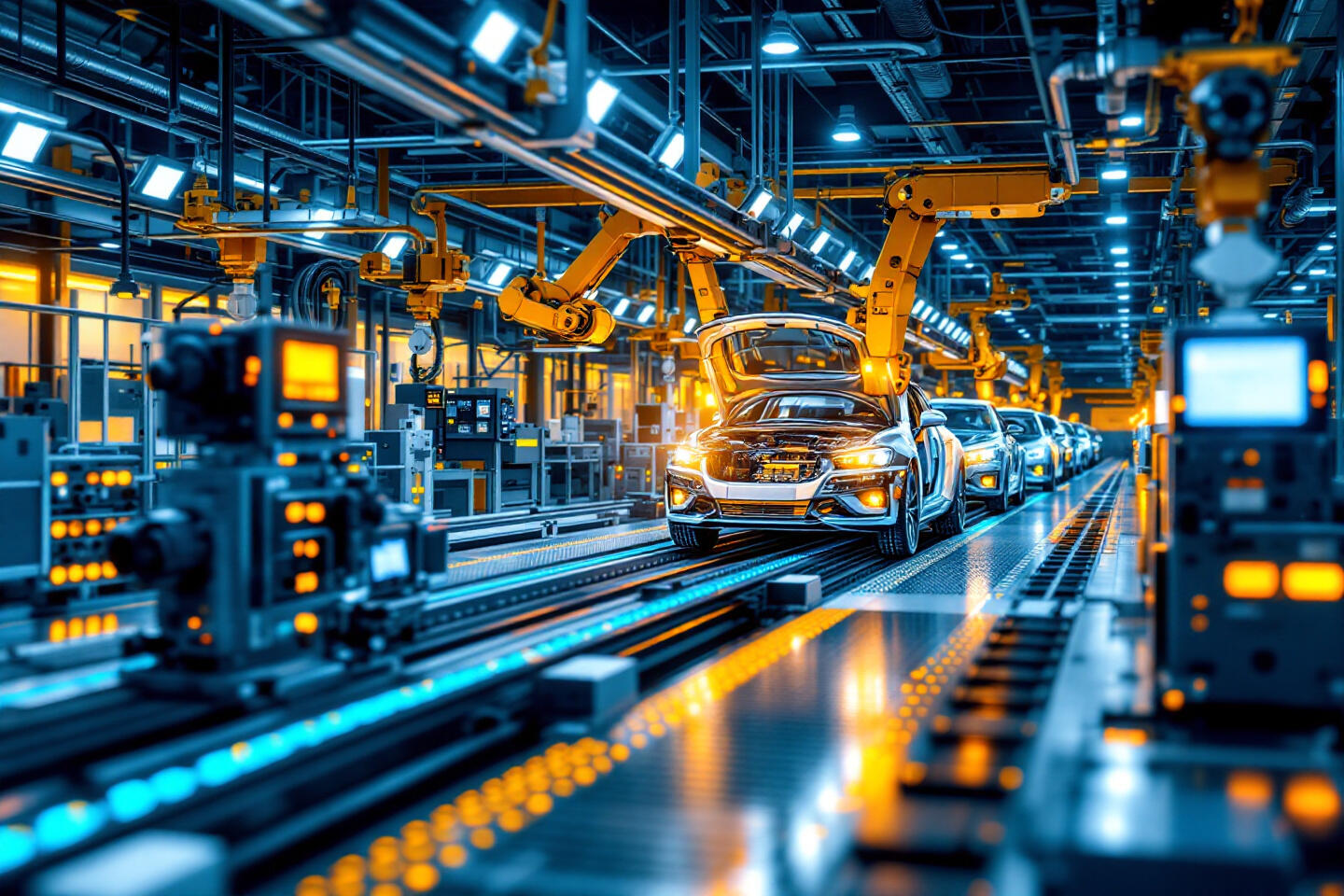

Is your company also facing the challenge of digitalising production processes? You're not alone. What used to be purely mechanical control processes has now evolved into an intelligent network of machines, systems, and people. In this article, you'll learn how to successfully master digital transformation and which control technologies can help you achieve this.

Fundamentals of Digital Transformation in Industry

The foundation of Industry 4.0 is built on the networking of your production systems through innovative control solutions. Machines communicate with each other and continuously exchange data. This enables better monitoring and control of your production. By analysing this data, you can optimise your processes and identify problems before they arise.

Modern Control Solutions as the Basis for Your Digitalisation

The foundation for successful digitalisation lies in innovative control solutions for your machines. These enable not only precise control over your production processes but also integration into networked systems. Optimised control solutions play a crucial role in precision and efficiency, particularly in cutting processes such as laser, water jet, or plasma cutting.

These Technologies Drive Your Digitalisation Forward

The Industrial Internet of Things (IIoT) is a crucial component of your technical foundation for digitalisation, along with cloud computing, big data, and wireless networks. Sensors in your machines and systems continuously capture important information – from temperature to production speed. This data is evaluated in real-time and enables quick responses to changes. With Clouver, a specialised IIoT platform, you can make your production processes transparent and identify optimisation potential.

How AI Revolutionises Your Production

Artificial Intelligence will become your most important ally in modern manufacturing. It helps you gain valuable insights from the wealth of data. Whether predicting maintenance, optimising control processes, or quality controls – AI algorithms recognise patterns and predict when your machines need service or where quality issues might arise.

Digital Twins: Your Path to Perfect Planning

Digital twins are a particularly exciting innovation. These virtual replicas of your real machines and control systems allow you to simulate changes on the computer first. This minimises your risks and saves valuable time when implementing new processes.

Integration and Challenges of Digitalisation

An important aspect of digitalisation is the integration of various control technologies and systems. Challenges such as system compatibility and data standardisation may arise and need to be mastered. With the right control solution, you create a unified basis for your systems' communication.

Make your IIoT environment secure and future-proof!

Discover how Clouver can help you minimise risks and maximise efficiency. Arrange a no-obligation consultation now - together we will find the right solution for your company.

Roadmaps and Best Practices for Implementation

A structured roadmap for implementing new control technologies can help you maintain overview and drive digitalisation in a targeted manner. Best practices include a step-by-step introduction beginning with pilot projects, regular employee training, and continuous adjustments based on feedback and collected data.

How to Implement Digitalisation in Practice

The good news: You don't have to implement everything at once. A gradual approach minimises your risks and increases the chances of success. First, analyse where digital control technologies can bring the greatest benefit to your company.

Your Employees Are the Key to Success

Don't forget: Your employees know the processes best. Involve them from the start and utilise their knowledge. At the same time, it's important to train them in using the new control technologies so they can use them effectively.

How to Secure Your Digital Production

With increasing connectivity, IT security becomes increasingly important. Protect your systems through firewalls, encryption techniques, and regular security audits. Your employees also play an important role – train them in IT security practices and adhere to international standards such as ISO/IEC 27001.

Sustainability Through Intelligent Control

Digital transformation also offers opportunities for greater sustainability. Through optimised control processes, you reduce energy consumption, use resources more efficiently, and reduce waste. Intelligent control systems help you improve your production's ecological footprint.

Your Opportunities for the Future

The development of Industry 4.0 continues to advance. New technologies like 5G will offer you even more possibilities. When you invest in modern control solutions now, you create the foundation for your future competitiveness.

Conclusion: Your Path to the Digital Future

Digital transformation isn't an option – it's your opportunity for the future. Although the change requires investment and perseverance, it offers enormous potential for increasing efficiency and new business opportunities.

Dimitri Koneger

Sales Manager

Have questions about the topic or want to learn more about our solutions?

Contact us and discover how our products can future-proof your machines. Let’s work together to find out how we can help take your production to the next level!

- +49 241 93681-500

- contact@procom-automation.de