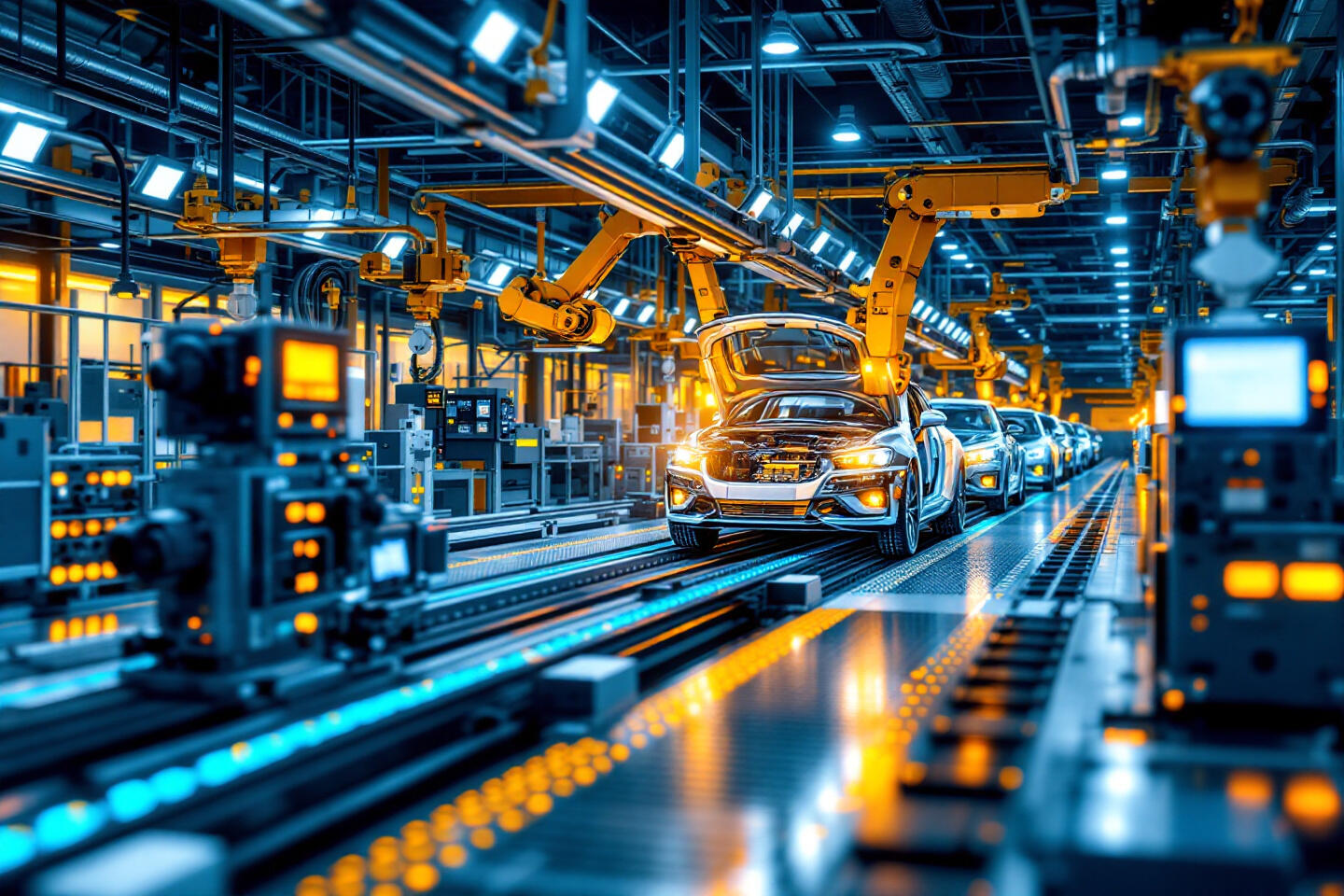

In today's fast-paced and technology-driven world, you face the challenge of making your production processes more efficient, cost-effective, and flexible to remain competitive. But how can the successful use of automation technologies in plant engineering be achieved? What solutions are available, and how can they specifically help to optimise processes?

What are the benefits of automation in plant engineering?

Through automation, you can significantly increase the efficiency of your production processes. Automated systems reduce error rates, lower operating costs, and increase the flexibility of your plants. They also contribute to improving occupational safety, as dangerous or monotonous tasks are taken over by machines. Overall, automation leads to higher productivity and enables your company to respond more quickly and accurately to market demands. Find out more about the benefits of automation.

How do CNC control solutions from ProCom Automation help?

CNC (Computerised Numerical Control) control solutions enable the precise control of machines such as milling machines, lathes, and cutting machines. The CNC controls from ProCom Automation offer high accuracy and repeatability, which is particularly advantageous in series production. Implementation can be complex, but the investment pays off through increased productivity and consistently high quality of manufactured parts. Learn more about CNC control solutions.

How do robotic systems increase efficiency?

Industrial robots and collaborative robots (cobots) take over repetitive and ergonomically stressful tasks that were previously performed by human employees. The robotic systems from ProCom Automation are designed to work safely alongside humans and make production processes flexible. They can be used in assembly, packaging, or quality control, thus significantly contributing to increased efficiency and error reduction. Learn more about robotic systems and their benefits.

What cutting technologies does ProCom Automation offer?

ProCom Automation relies on state-of-the-art laser, waterjet, and knife cutting systems. Laser cutting offers exceptional precision and is ideal for fine details. Waterjet cutting allows the processing of thick and resistant materials without thermal deformation. Knife cutting is efficient for soft materials and fast production cycles. The choice of the right technology depends on the specific requirements of your production. More about cutting technologies.

How does Clouver support the digitisation of workflows?

By digitising workflows, you can monitor and continuously optimise your production processes. The Clouver production monitoring software from ProCom Automation allows you to collect, analyse, and visualise real-time data. This helps you identify bottlenecks and make processes more efficient. Examples include the integration of ERP systems and the use of the Industrial Internet of Things (IIoT) to seamlessly network all production steps. More information on digitisation in the industry.

How can you achieve efficiency improvements with Clouver?

Regular efficiency analyses are essential to continuously improve the performance of your systems. With Clouver, you can conduct comprehensive analyses to identify bottlenecks and implement targeted improvement measures. Case studies show how companies have increased their production capacities and lowered operating costs by using Clouver. More about achieving efficiency improvements with Clouver.

How does ProCom Automation improve quality control?

Automated quality assurance systems are an essential part of process optimisation. ProCom Automation integrates advanced sensors and testing devices into your production line to monitor product quality in real-time. These systems immediately detect defects, reducing scrap rates and rework. This ensures consistently high product quality and increases customer satisfaction. Learn more about quality control with ProCom Automation.

How does ProCom Automation integrate the Industrial Internet of Things?

The Industrial Internet of Things (IIoT) connects your machines and enables comprehensive real-time monitoring and control. With Clouver, you can intelligently network your production systems, collect and analyse real-time data. This leads to greater transparency and enables you to react proactively to changes in the production process and make optimisations. More about IIoT use cases.

What are digital twins and how do you use them?

Digital twins are virtual models of your physical systems that can be used to simulate and optimise your production processes. With Clouver, you can create digital twins that provide detailed insights into the operation of your systems. These models help you simulate processes, identify potential problems early, and make adjustments before they need to be implemented in real production. Learn more about digital twins.

How does predictive maintenance work with Clouver?

Predictive maintenance reduces downtime and significantly lowers maintenance costs. By using sensors that continuously monitor the condition of your machines, Clouver can schedule maintenance work in good time before failures occur. This increases the lifespan of your systems and ensures a continuously smooth production flow. More about predictive maintenance with Clouver.

What are the benefits of cloud-based control systems?

Cloud-based control systems offer you high flexibility and scalability. With Clouver, you can move your control systems to the cloud, allowing you to access your production data from anywhere. This facilitates remote monitoring and control of your systems but also brings challenges in terms of security and data integrity that need to be carefully managed. More about cloud-based control systems.

Where are CNC machines used?

In the automotive sector, automation solutions greatly improve the efficiency and quality of your production processes. ProCom Automation offers specialised robots for assembly and precise CNC machines for parts manufacturing. These systems enable faster production with consistently high quality, which is crucial in the highly competitive automotive industry. More about CNC machines.

Tailored Solutions for Your Production!

ProCom develops control solutions perfectly tailored to your needs. Whether laser, waterjet, or knife cutting – we optimise your processes. Contact us for a personalised consultation!

What role does AI play in automation?

Artificial Intelligence (AI) optimises your production processes through advanced data analysis and machine learning. With Clouver, you can integrate AI algorithms that learn from historical data and make predictions to continuously improve your processes. Examples include predictive analysis to forecast maintenance needs or adaptive control systems that automatically adjust to changing production conditions. More about AI in automation.

How do you use machine learning in process control?

Machine learning models can significantly improve process control by continuously learning from new data and adapting. This results in more precise control and faster response times to changes in the production process. Challenges lie in ensuring data quality and model accuracy, but with Clouver, you can successfully overcome these hurdles and fully leverage the benefits of machine learning. More about machine learning in process control.

How do cobots work with humans?

Cobots work safely with human employees and increase flexibility in your production. ProCom Automation offers cobots that are easy to program and integrate, allowing you to quickly respond to new requirements. Safety aspects such as collision avoidance and ergonomic interfaces are central to ensuring smooth collaboration. More about cobots.

How do smart sensors and data acquisition help?

Smart sensors capture and analyse data in real-time, contributing to process optimisation and predictive maintenance. With Clouver, you can efficiently collect and use this data to make informed decisions. Smart sensors enable detailed monitoring of your production processes and help you identify and address bottlenecks and inefficiencies early. More about smart sensors.

What economic aspects are important?

Calculating the return on investment (ROI) is crucial to assess the profitability of your automation projects. By investing in ProCom Automation and Clouver, you can achieve significant cost savings and efficiency gains. Case studies show how companies have positively impacted their ROI through targeted automation measures by reducing operating costs and increasing productivity. More about economic aspects.

How do you optimise costs?

Cost optimisation strategies include the efficient use of resources and the implementation of advanced technologies. With the solutions from ProCom Automation, you can design your production processes to consume less energy and materials without compromising the quality of your products. This leads to long-term reductions in operating costs and increases your competitiveness. More about cost optimisation.

How do you increase energy efficiency?

Measures to increase energy efficiency are not only cost-saving but also environmentally friendly. ProCom Automation offers energy-efficient machines and processes that reduce the energy consumption of your systems. By optimising energy flows and using modern technologies, you can lower operating costs and contribute to environmental protection. More about energy efficiency.

How do you develop your staff?

Training and further education of your employees are crucial for the success of automation projects. ProCom Automation offers comprehensive training programmes that enable your employees to effectively use new technologies. Additionally, effective change management supports the acceptance and integration of automation solutions in your company, increasing the productivity and satisfaction of your employees. More about personnel development.

What safety standards are important?

Compliance with safety standards such as ISO and IEC is essential for the safe operation of automation systems. ProCom Automation ensures that all solutions comply with applicable safety standards by implementing modern safety mechanisms and regular inspections. This protects both your employees and your equipment from potential hazards. More about safety standards.

How do you protect your systems from cyberattacks?

Protecting your automation systems from cyberattacks is essential. With Clouver, you implement comprehensive cybersecurity measures such as firewalls, intrusion detection systems, and regular security updates. These protective measures prevent unauthorised access and ensure the integrity of your production data, allowing you to focus on your core processes. More about protection against cyberattacks.

Why is CE conformity important?

The CE marking is important for international trade and confirms compliance with European safety standards. ProCom Automation ensures that all products and solutions are CE compliant, facilitating market entry and the distribution of your products in Europe. This creates trust with your customers and business partners, as the quality and safety of your products are guaranteed. More about CE conformity.

How do you ensure occupational safety?

Occupational safety measures include training, providing protective equipment, and regularly inspecting your systems. ProCom Automation helps you create a safe working environment by offering innovative safety solutions and comprehensive training programmes. This contributes to the health and safety of your employees and minimises the risk of workplace accidents. More about occupational safety.

Conclusion

Plant engineering automation has proven to be an indispensable part of modern production processes. By integrating advanced technologies and intelligent control solutions from ProCom Automation and Clouver, you can increase your efficiency, reduce production costs, and maximise the precision of your production processes. ProCom Automation offers customised solutions that are perfectly tailored to the individual requirements of your operation. From CNC controls to comprehensive automation solutions – ProCom Automation helps you stay competitive and future-proof.

Are you interested in optimising your production processes? Visit our blog for more information or book a free demo version of Clouver to see how our IIoT solutions can help you make informed decisions based on reliable data. Contact us now for a non-binding consultation and find out how ProCom Automation can take your production to the next level.

Learn more about ProCom Automation

Book demo version of Clouver

Sergej Gigel

Senior Sales Manager

Have questions about the topic or want to learn more about our solutions?

Contact us and discover how our products can future-proof your machines. Let’s work together to find out how we can help take your production to the next level!

- +49 241 93681-500

- contact@procom-automation.de