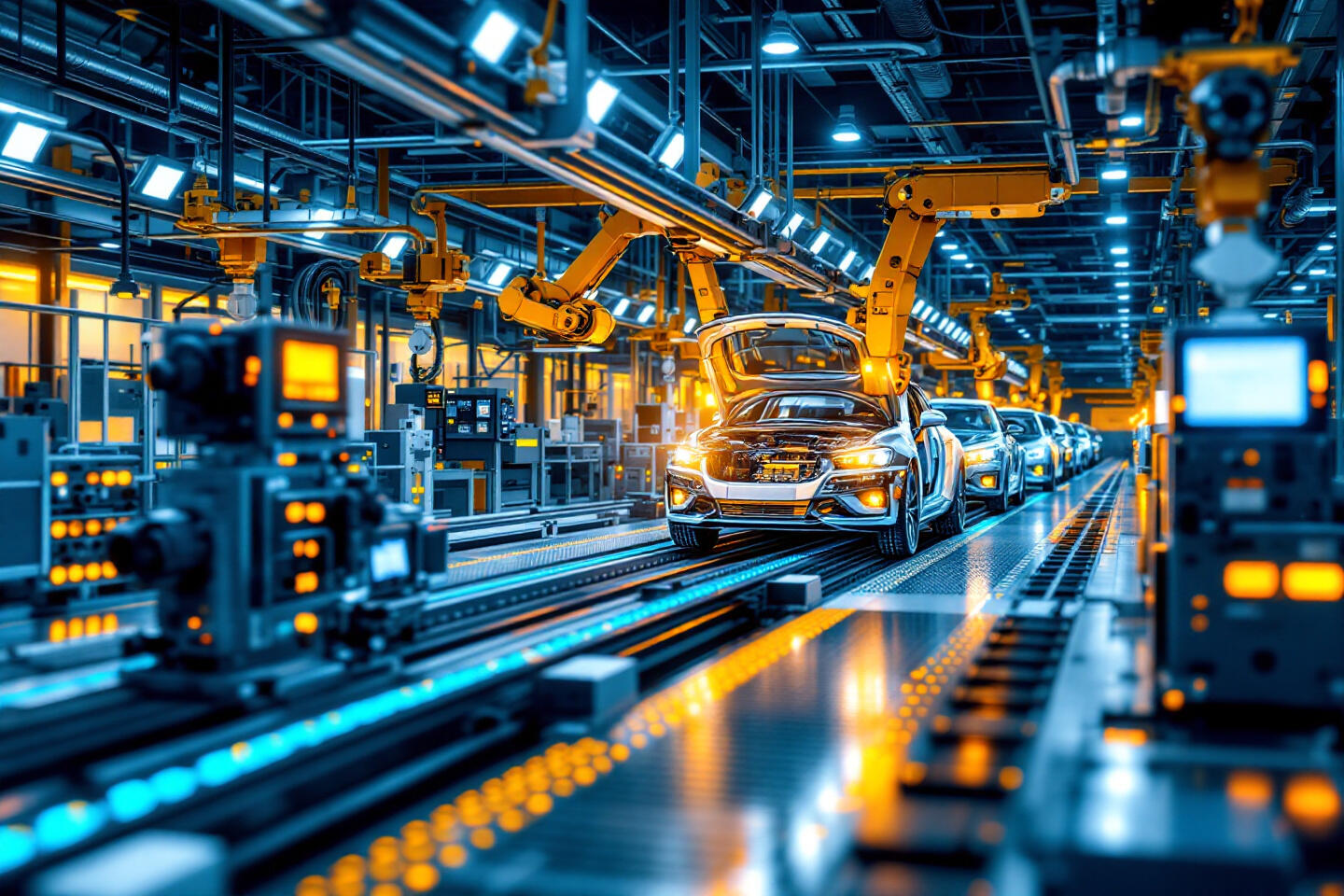

In today's fast-paced and highly competitive business world, automation has become an indispensable tool for small and medium-sized enterprises (SMEs). But what does automation mean for SMEs, and how can it benefit you? In this article, we explore the relevance of automation for SMEs and address key questions that many business owners have: What technologies and systems are available? What are the costs and the return on investment (ROI)? What challenges and opportunities does implementation bring?

By reading this article, you'll gain valuable insights into various aspects of automation—from technical details and economic considerations to practical tips for successful implementation. Learn how to optimise your production processes, reduce costs, and sustainably increase your company's efficiency. Be inspired and discover the potentials that automation solutions can offer your business.

What Does Automation Mean for SMEs?

Automation in SMEs refers to the implementation of technologies and systems that automate manual processes and tasks in small and medium-sized enterprises. This includes the automation of production, administration, data collection and analysis, as well as other operational processes. By using automation technologies, you can handle repetitive tasks more efficiently, minimise human errors, and free up valuable resources that can be used for strategic initiatives.

What Benefits Does Automation Offer for Medium-Sized Enterprises?

Automation offers numerous benefits for medium-sized enterprises. You can increase efficiency by accelerating and optimising processes. Error rates decrease, leading to improved product quality. Additionally, you reduce operating costs by reducing manual effort and resource utilisation. Another advantage is the ability to focus more on value-added activities rather than repetitive tasks. Moreover, automation strengthens your company's competitiveness and innovation by enabling you to respond more quickly to market changes and integrate new technologies.

What is the Current State of Automation in SMEs?

Many medium-sized enterprises have already begun implementing automation solutions to optimise their production processes and remain competitive. The use of technologies such as the Industrial Internet of Things, cloud computing, and artificial intelligence is steadily increasing. Companies like ProCom Automation offer state-of-the-art CNC machines and cutting machines specifically tailored to the needs of SMEs. Additionally, the Clouver production monitoring software enables the real-time collection and analysis of all production data, leading to a significant increase in overall productivity.

How Can You Optimise Machine Management and Process Control?

A central aspect of automation is effective machine management and process control. With an advanced machine manager from ProCom Automation, you can efficiently configure and manage your machines. Different operating modes such as production mode, setup mode, and maintenance mode allow you to precisely adapt machine performance to the respective tasks. Features such as automatic height control and various cutting modes contribute to the optimisation of production processes. By integrating these systems, you can identify and eliminate bottlenecks early, significantly improving production quality and speed.

How Do Cloud-Based Automation Solutions Like Clouver Help?

Clouver is an Industrial Internet of Things-based platform that collects, analyses, and visualises production data. With Clouver, you can conduct real-time monitoring and analysis of your production processes. This helps you to increase production efficiency, minimise downtime, and improve overall productivity. By connecting your machines and sensors to Clouver, real-time data is collected and visualised on user-friendly dashboards. This gives you a comprehensive overview of your production facilities' status at any time, allowing you to quickly respond to deviations.

How Can You Utilise Data Collection and Analysis?

Continuous data collection through sensors (e.g., pressure, temperature) is an essential component of automation. The collected data is stored in the cloud and analysed using analytics tools to identify patterns and potential optimisations. Through data visualisation and error detection, you can continuously improve production quality and efficiency. Clouver provides you with powerful analytics capabilities, enabling you to make informed decisions based on precise data.

How Do You Optimise Production Through the Industrial Internet of Things?

Integrating the Industrial Internet of Things (IIoT) into your production processes allows the networking of all production facilities and the collection of real-time data. This contributes to the optimisation of overall equipment effectiveness (OEE) and helps you proactively avoid downtime. With IIoT devices, you can continuously monitor your machines' performance and immediately respond to deviations. This leads to more efficient resource utilisation and improved production planning. ProCom Automation offers customised IIoT solutions tailored to the needs of medium-sized enterprises.

How Do You Integrate Different Automation Systems?

Integrating different automation systems can be challenging. ProCom Automation uses standardised interfaces such as OPC UA and EtherCAT to seamlessly connect different systems and ensure smooth operation. These standardised interfaces allow various automation components to communicate effortlessly, reducing the overall complexity of your automation network.

What is Predictive Maintenance and How Does It Help You?

Predictive Maintenance uses data analysis tools to monitor the condition of your machines and detect maintenance needs early. This minimises unplanned downtime and increases your production facilities' efficiency. By implementing ProCom Automation's Predictive Maintenance solutions, you can extend your machines' lifecycle and enhance operational safety.

Clouver: Your IIoT Solution for Maximum Transparency!

Stay on top of every process in your manufacturing – from machine status to production data. Clouver enables you to make informed decisions based on reliable data. Request your free demo today!

How Do You Ensure Quality Through Automated Processes?

Automated quality assurance processes ensure consistent results and improve product quality. With sensors and cameras, you can monitor product quality in real-time. ProCom Automation offers advanced solutions for integrating these technologies into your production processes, enabling you to respond immediately to quality deviations and take appropriate measures.

How Do You Calculate ROI for Automation Projects?

Calculating return on investment (ROI) is crucial for evaluating the economic viability of automation projects. You should consider all costs and savings to make informed decisions. ProCom Automation assists you in conducting a detailed ROI analysis, allowing you to clearly identify your investments' financial benefits.

What Cost Analyses are Important for Different Automation Levels?

A comparison of the costs and benefits of different levels of automation shows that long-term cost savings are possible through automation. A detailed cost analysis helps you find the best solution for your company. ProCom Automation offers customised solutions optimally tailored to your financial capabilities and requirements.

What Funding Opportunities are Available for SMEs?

There are various funding programmes and grants that support SMEs in implementing automation solutions. These can include grants, low-interest loans, or tax incentives. ProCom Automation is happy to advise you in applying for funding and helps you find the right programmes for your automation project.

What is the Total Cost of Ownership (TCO) and How Do You Calculate It?

Calculating the Total Cost of Ownership (TCO) is important to understand the long-term financial impact of automation. Automation can positively influence TCO through efficiency increases and cost savings. With ProCom Automation's comprehensive solutions, you can accurately calculate and optimise the TCO of your automation projects.

How Do You Implement Automation Solutions Gradually?

A gradual implementation of automation solutions minimises risks. Start with pilot projects to test the solutions and scale them up after successful tests. ProCom Automation supports you in planning and implementing this gradual introduction, ensuring that you can safely and effectively leverage the benefits of automation.

How Important is Change Management in Automation?

Effective change management is crucial to successfully managing changes in your company. Involve your employees in the automation process and offer regular training. This ensures that all stakeholders understand and optimally use the new systems. ProCom Automation provides comprehensive support in the area of change management to make the transition as smooth as possible.

Why Are Employee Training and Qualifications Important?

Regular training and further education are necessary to keep your employees' knowledge and skills up to date. This promotes the acceptance and successful use of automation technologies. ProCom Automation offers customised training programmes specifically tailored to your company's needs.

How Do Best Practices and Case Studies Help in Automation?

Best practices and case studies provide valuable guidance in implementing automation solutions. Successful projects from other companies can serve as role models and their strategies can be adapted. ProCom Automation provides you with a variety of case studies that help you identify proven methods and implement them in your own company.

Conclusion

Automation in SMEs offers enormous potential for increasing efficiency and productivity. Using modern technologies like the Industrial Internet of Things-based platform Clouver, you can monitor and analyse your production processes in real-time. This enables precise adjustment of operating parameters to identify bottlenecks early, minimise downtime, and sustainably increase overall productivity. Features such as automatic height control, various operating modes, and the ability to capture and analyse real-time data significantly improve production quality and efficiency.

Want to learn more about how ProCom Automation can support your company in automation? Visit our article for further content or book a demo version of Clouver to experience the benefits of this advanced technology for yourself. Click here for more information.