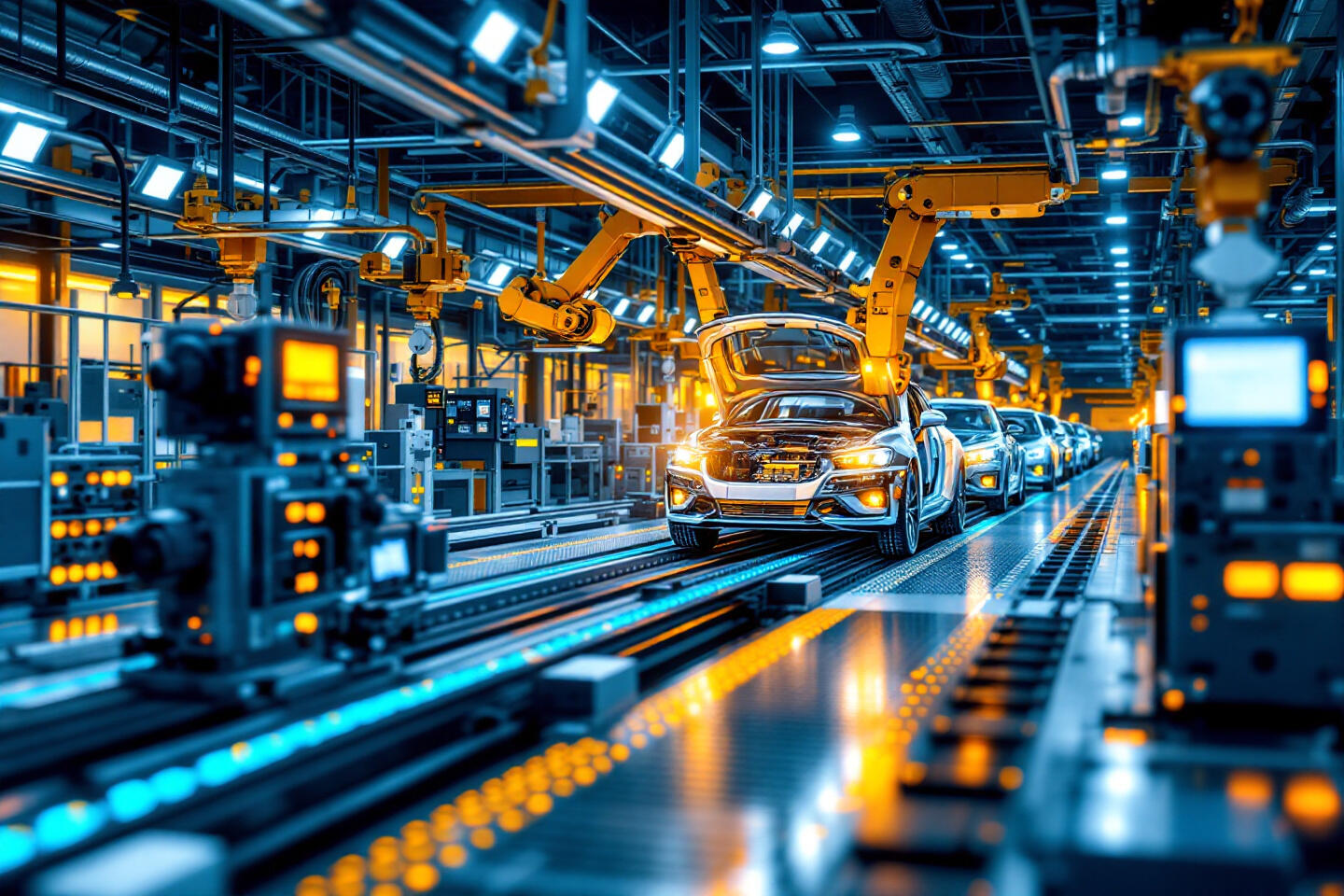

Why are IIoT Sensors so Important?

In today's industrial landscape, Industrial Internet of Things (IIoT) sensors are a critical component that can make the difference between success and failure. These sensors form the backbone of modern automation solutions and enable precise real-time data collection, which is essential for optimising production processes. But why are IIoT sensors so important, and what challenges and opportunities do they offer?

How Do IIoT Sensors Contribute to Process Optimisation?

IIoT sensors play a central role in Industry 4.0 by contributing to process optimisation, quality assurance, and predictive maintenance. They enable precise monitoring of machine conditions, control of process parameters, and ensuring product quality. By collecting and analysing this data, companies can identify bottlenecks, make processes more efficient, and react early to potential problems. Sensor data is the foundation for intelligent decisions and significantly contributes to a company’s competitiveness and innovative strength.

How Does the Clouver Platform by ProCom Automation Help You?

By integrating IIoT sensors into your machine controls from ProCom Automation, especially with the Clouver platform, you can not only increase efficiency but also enable long-term cost savings. Clouver offers comprehensive data collection and analysis, enabling improved process monitoring and control and the ability to make data-driven decisions in real-time. Sensors on the Clouver platform are highly intelligent devices that provide context-sensitive data and support complex analyses. This leads to higher accuracy in data interpretation and enables the development of more precise optimisation strategies.

What is the Industrial Internet of Things (IIoT)?

The Industrial Internet of Things (IIoT) refers to the networking of machines, sensors, and control systems in industrial environments. This networking enables the continuous collection and analysis of data in real-time, leading to improved decision-making and process optimisation. By integrating IIoT technologies, companies can identify inefficient processes, increase productivity and respond flexibly to market demands.

What Role Do IIoT Sensors Play in the Industry?

IIoT sensors are specialised devices that measure physical parameters such as temperature, pressure, humidity, vibrations, and much more and send this data in real-time to a central platform like Clouver from ProCom Automation. These sensors are essential for the continuous monitoring and optimisation of production processes. They enable precise monitoring of machine conditions, control of process parameters, and ensuring product quality. By collecting and analysing this data, companies can identify bottlenecks, optimise processes, and respond early to potential problems.

How Does the Technical Integration of IIoT Sensors Work?

The Clouver platform from ProCom Automation seamlessly integrates IIoT sensors to enable comprehensive data collection and analysis. This integration offers numerous advantages, including improved process monitoring and control as well as the ability to make data-driven decisions in real-time. Sensors on the Clouver platform are not just simple data collectors; they are highly intelligent devices that provide context-sensitive data and support complex analyses. This leads to higher accuracy in data interpretation and enables the development of more precise optimisation strategies.

How Do You Connect CNC Controls and IIoT Sensors?

A seamless communication between CNC control and IIoT sensors is crucial for real-time data collection and analysis. The OPC UA interface from ProCom Automation enables this smooth integration and ensures that data is transmitted quickly and reliably. Install the OPC UA software on your CNC control from ProCom Automation, configure the sensors, thoroughly test the connection, and continuously monitor the data transmission to detect and resolve any connection issues early.

Why is Real-Time Data Collection Important for Cutting Processes?

Real-time data collection is particularly crucial in the cutting industry, as it allows immediate responses to process deviations. The Clouver gateway function sends sensor data in real-time to the platform, allowing for immediate monitoring and adjustment of cutting processes. Implement real-time data collection to be able to respond immediately to deviations in the cutting process. This increases the accuracy and consistency of production quality and minimises downtime due to unexpected process problems.

How Do You Optimise Processes with IIoT Sensors?

IIoT sensors enable automatic adjustment of cutting parameters based on real-time data. This significantly increases production quality and efficiency, as the cutting machines from ProCom Automation can immediately respond to changes in the production process. Collect relevant sensor data such as material thickness, temperature, and vibration patterns, create rules for automatic adjustment of cutting parameters, and implement these rules directly in your CNC control from ProCom Automation.

Get the Best Out of Your Production with Clouver!

Connect your machines and gain valuable insights into your production processes. Reduce unused capacity, optimise resource utilisation, and increase your revenue. Contact us today for a no-obligation consultation!

What is Predictive Maintenance and How Can It Help You?

Predictive maintenance uses sensor data to predict maintenance needs and avoid downtime. This leads to higher machine availability and lower maintenance costs, as proactive measures can be taken before serious problems arise. Continuously collect data on machine conditions such as vibration, temperature, and utilisation, analyse this data to recognise patterns indicating upcoming maintenance needs, and plan preventive maintenance measures based on these insights.

How Do You Ensure Quality Through Continuous Monitoring?

Continuous monitoring of cutting quality through sensor data ensures that production standards are met and allows for immediate adjustments in case of deviations. Collect data on cutting quality such as edge quality and accuracy with IIoT sensors, continuously compare this data with the target values, and automatically adjust cutting parameters when deviations are detected.

How Do You Integrate IIoT Sensors into Existing Machine Controls?

The integration of IIoT sensors into existing machine controls can be facilitated by the flexible interfaces of ProCom Automation. Check the compatibility of your existing CNC control from ProCom Automation with the desired IIoT sensors, use the EoE gateway software from ProCom Automation to integrate the sensors into your control systems, thoroughly test the integration, and train your team in handling the new sensors and the Clouver platform.

What Successful Implementations Exist?

Learn from successful implementations in the cutting industry to identify best practices and success factors. Research case studies and success stories, analyse the applied methods and technologies, and transfer the gained insights to your own implementation projects.

How Do You Introduce IIoT Components Gradually?

A gradual introduction of IIoT components minimises risks and maximises the return on investment (ROI). Start with a pilot project to test the integration of IIoT sensors and gain initial insights, scale the implementation based on the results of the pilot project, and continuously monitor the performance of the IIoT components.

How Do You Ensure Data Security?

Data security is an essential aspect of using IIoT sensors. It is ensured through secure data transmission, encryption standards, and access controls. Clouver from ProCom Automation offers comprehensive security measures to protect the integrity and confidentiality of your data. Encrypt the data during transmission and storage, implement access controls, and conduct regular security updates and audits.

What Economic Benefits Do IIoT Sensors Offer?

The use of IIoT sensors can lead to a significant increase in return on investment (ROI). By preventive maintenance and real-time monitoring, costs can be reduced, and productivity can be increased. Additionally, process optimisation enables more efficient use of resources, leading to sustainable cost savings.

What Are the Future Perspectives for IIoT Sensors and Clouver?

The future perspectives for IIoT sensors and the Clouver platform from ProCom Automation are promising. Advances in sensor technology, the integration of artificial intelligence (AI) and machine learning, and the expansion of the Clouver platform will further increase the efficiency and competitiveness of the manufacturing industry.

Frequently Asked Questions About IIoT Sensors as a Critical Component

What Are IIoT Sensors and Why Are They Important?

IIoT sensors (Industrial Internet of Things) are devices that measure physical parameters such as temperature, pressure, humidity, and vibrations and transmit this data in real-time to a central platform like Clouver from ProCom Automation. They are important because they enable continuous monitoring and optimisation of production processes, leading to higher efficiency and lower costs.

How Do IIoT Sensors Contribute to Process Optimisation?

IIoT sensors collect real-time data that can be used for automatic adjustment of cutting parameters, predictive maintenance, and quality assurance through continuous monitoring. This leads to higher efficiency and productivity by identifying bottlenecks and optimising processes.

What Role Do IIoT Sensors Play in the Clouver Platform?

In the Clouver platform from ProCom Automation, IIoT sensors serve as a central data source. They collect and transmit important process and machine data, which can then be analysed and used to optimise production processes. This enables data-driven decision-making, making the entire production chain more efficient.

How Is Data Security Ensured When Using IIoT Sensors?

Data security is ensured through secure data transmission, encryption standards, and access controls. Clouver from ProCom Automation offers comprehensive security measures to protect the integrity and confidentiality of the data, ensuring your production data is safe and secure.

What Economic Benefits Does the Use of IIoT Sensors Offer?

The use of IIoT sensors can lead to a significant increase in return on investment (ROI). By preventive maintenance and real-time monitoring, costs can be reduced, and productivity increased. Additionally, process optimisation enables more efficient use of resources, leading to sustainable cost savings.

How Can IIoT Sensors Be Integrated into Existing Machine Controls?

The integration of IIoT sensors into existing machine controls is carried out gradually and can be supported by the flexible interfaces of ProCom Automation. By using the EoE gateway software and the OPC UA interface, you can seamlessly integrate the sensors into your existing systems and take advantage of real-time data collection.

What Are the Future Perspectives for IIoT Sensors and the Clouver Platform?

The future perspectives include the further development of the Clouver platform, the integration of new sensor technologies, and the use of artificial intelligence (AI) for further process optimisation. These innovations will further increase the efficiency and competitiveness of the manufacturing industry and open up new possibilities for optimising production processes.

Conclusion

IIoT sensors are a critical component in modern industry, enabling companies to collect precise data and make informed decisions. They contribute significantly to the optimisation of production processes, improvement of maintenance strategies, and overall efficiency enhancement. By integrating IIoT sensors into the machine controls of ProCom Automation, you can not only reduce your operating costs but also increase product quality and customer satisfaction.

Do you want to learn more about how IIoT solutions can drive your company forward? Make your IIoT environment secure and future-proof! Discover how Clouver from ProCom Automation can help you minimise risks and maximise efficiency – together, we will find the right solution for your company. Visit our blog for more content or book a demo version of Clouver to experience the benefits for yourself.

About ProCom Automation

ProCom Automation is a leader in the development of CNC machines and cutting machines that can be seamlessly integrated into modern IIoT environments. With our expertise and the best technologies in the industry, we ensure that your production processes are efficient, safe, and future-proof.

About Clouver

Clouver is the most advanced production monitoring software on the market, developed by ProCom Automation. With Clouver, you can centrally manage all your IIoT sensors, analyse data in real-time, and make informed decisions that optimise your production processes and keep your company competitive.

Sergej Gigel

Senior Sales Manager

Have questions about the topic or want to learn more about our solutions?

Contact us and discover how our products can future-proof your machines. Let’s work together to find out how we can help take your production to the next level!

- +49 241 93681-500

- contact@procom-automation.de