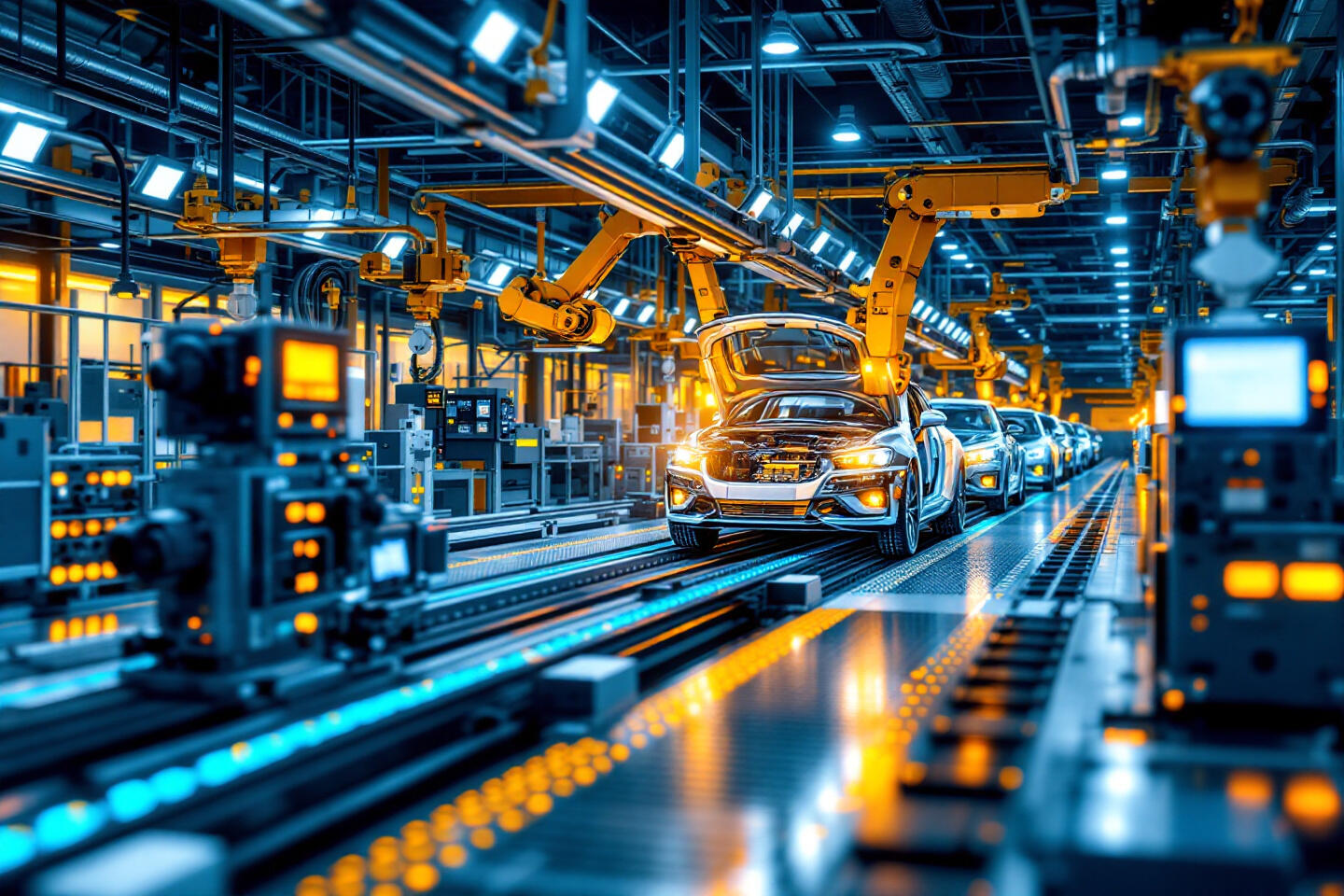

In today's fast-paced Industry 4.0 world, Industrial Internet of Things (IIoT) technologies are the key to transforming and optimising production processes. But what exactly does this term mean, and why is it so crucial for companies? Many companies face the challenge of efficiently networking their machines and systems to capture and analyse real-time data. This raises questions such as: What components are necessary? How can automation and process optimisation be improved? And what about data security?

In this blog post, you will get a comprehensive overview of the most important Industrial Internet of Things technologies that can revolutionise your production processes. You will learn how intelligent control systems, predictive maintenance, and cloud connectivity can help you increase efficiency and reduce costs. We also shed light on the latest trends and provide practical tips for implementation. By reading this post, you will gain valuable insights and concrete recommendations for fully leveraging the potential of Industrial Internet of Things technologies and making your company future-proof.

What Are Industrial Internet of Things Technologies and Why Are They Important?

Industrial Internet of Things refers to the networking of machines, sensors, and control systems in industrial environments. These technologies enable the real-time collection and analysis of data to optimise processes and increase efficiency. With Industrial Internet of Things, you can continuously monitor the condition of your machines, detect production bottlenecks early, and take immediate action to prevent downtime. This not only leads to cost savings but also to higher product quality and more flexible production.

How Have Industrial Internet of Things Technologies Developed and What Are the Current Trends?

The development of Industrial Internet of Things technologies began with the introduction of sensors and control systems in industrial production. In recent years, the increasing digitisation and networking of machines have made Industrial Internet of Things a central component of Industry 4.0. Current trends include the integration of Artificial Intelligence (AI), the use of Edge Computing for on-site data processing, and the implementation of 5G technologies for faster and more reliable communication. These developments enable companies to create even more data-driven and efficient production systems.

What Are the Benefits and Challenges of Implementing Industrial Internet of Things Technologies?

Industrial Internet of Things technologies offer numerous benefits, including improved process monitoring and control, increased efficiency and productivity, reduced downtime through predictive maintenance, and more informed decision-making through data analysis. However, there are also challenges in implementation. Integrating existing legacy systems can be complex, as can ensuring network security and data protection. Additionally, implementing Industrial Internet of Things technologies requires training and qualifying employees to effectively use the new systems. With the right strategies and partners, such as Clouver for production monitoring software, these challenges can be successfully mastered.

How Does Machine Communication and Networking Work?

Machine communication and networking are central elements of Industrial Internet of Things systems. Industrial communication standards like EtherCAT and OPC UA enable reliable and fast data transmission between machines, sensors, and control systems. The interoperability of different systems is crucial to ensure smooth operations. Additionally, cybersecurity aspects play an important role in ensuring data integrity and protection against unauthorised access. Procom Automation offers leading solutions with their CNC and cutting machines, which can be seamlessly integrated into Industrial Internet of Things environments.

What Role Do Sensor Technology and Data Collection Play?

Sensors are the heart of data collection in Industrial Internet of Things systems. There are various types of sensors suitable for different applications, such as temperature, pressure, and humidity sensors. These sensors continuously collect data and transmit it in real-time to central systems for further analysis. The accuracy and reliability of the collected data are crucial for optimising production processes. By using high-quality sensors from Procom Automation, you can ensure that your data is precise and reliable.

How Do Intelligent Control Systems Help?

Intelligent control systems like the CNC300-Inspector from Procom Automation enable the integration of control systems into existing infrastructures. These systems offer numerous advantages, including improved process control, increased efficiency, and remote monitoring capabilities. With advanced features such as automatic error detection and correction, you can optimise your production processes while reducing operating costs.

Why Is Cloud Connectivity Important?

Cloud-based solutions like the Clouver Gateway from Clouver offer numerous benefits for Industrial Internet of Things systems. They enable the storage and analysis of large data volumes and provide a central platform for monitoring and controlling processes. With cloud connectivity, you can flexibly access your data, analyse it at any time, and make informed decisions. Security aspects of cloud usage are crucial. Clouver ensures that your data is securely stored and transmitted so that you can focus on optimising your production processes.

How Does Predictive Maintenance Work?

Predictive maintenance is a proactive maintenance strategy based on the analysis of machine data. By monitoring operational parameters, you can detect and address potential problems early before a breakdown occurs. Technologies and methods for implementing predictive maintenance include the installation of sensors and the development of algorithms to predict maintenance needs. With solutions from Clouver, you can ensure that your maintenance processes are efficient and effective, extending your machines' lifespan and reducing operating costs.

How Does Automatic Adaptability Help?

Adaptive control systems enable automatic adjustment of processes to changing conditions. This is particularly useful in production environments that need to respond flexibly to different materials and production requirements. For example, production parameters can be automatically adjusted to the properties of various materials to achieve optimal results. Additionally, adaptive systems can optimise energy consumption and resource utilisation, reducing both costs and environmental impact.

How Does Real-Time Process Monitoring Work?

Technologies for real-time monitoring enable continuous monitoring of processes and immediate response to deviations. This leads to improved process control and reduced downtime. With real-time data, you can identify problems immediately and take action before they negatively impact production. Practical examples show how real-time monitoring can contribute to optimising production processes by allowing immediate adjustment of production parameters and thereby increasing efficiency.

How Does Operational Data Collection Work?

Methods and technologies for operational data collection include the installation of data collection hardware and software on machines. The collected data is stored in a central database and regularly analysed to identify optimisation potentials. With solutions from Clouver, you can ensure that your operational data is efficiently collected, stored, and analysed. This enables you to make informed decisions and implement continuous improvements in your production processes.

How Do OPC UA Interfaces Help?

OPC UA interfaces enable reliable and fast data transmission between different devices and systems. The use of OPC UA offers numerous advantages, including improved interoperability and support for process optimisation and decision-making. By integrating OPC UA interfaces into your Industrial Internet of Things infrastructure, you can ensure seamless communication between different machines and systems, leading to more efficient and flexible production.

What Are the Benefits of Cloud-Based Analysis Tools?

Cloud-based analysis tools offer numerous benefits, including the storage and analysis of large data volumes as well as the identification of patterns and trends in the data. These tools enable you to gain deeper insights into your production processes and make informed decisions. Challenges in using cloud-based analysis tools include ensuring data security and privacy protection. Clouver ensures that your data is securely stored and processed in the cloud so that you can fully leverage the benefits of cloud analytics.

How Does Big Data Processing Work?

Technologies and methods for big data processing enable the analysis of large data volumes and the identification of optimisation potentials. Application cases and benefits include improving process control and supporting decision-making processes. By leveraging big data, you can identify patterns in production data, point out hidden efficiency improvements, and use these insights to continuously enhance your processes.

Your Partner for Innovative Automation Solutions!

ProCom offers the perfect combination of intelligent software, premium hardware, and comprehensive support. Whether knife, laser, or waterjet cutting – we'll develop the ideal solution for your production needs. Arrange your consultation today and get started!

Where Are Industrial Internet of Things Technologies Applied?

Manufacturing Automation

Manufacturing automation involves the implementation of robots and automation systems to perform manual processes. Examples and benefits include increased efficiency and productivity as well as reduced errors and downtimes. Challenges and solutions include integrating existing systems and training employees. Procom Automation offers leading solutions in the field of manufacturing automation, which can be seamlessly integrated into your production environment and help you efficiently achieve your production goals.

Quality Control

Technologies and methods for quality control include installing sensors and cameras to monitor product quality. Application cases and benefits include improving product quality and reducing scrap and rework. With high-quality quality control systems from Procom Automation, you can ensure that your products meet the highest standards and deviations are quickly detected and corrected.

Maintenance Management

Methods and technologies for maintenance management include implementing predictive maintenance and using data analysis to plan maintenance actions. Benefits and challenges include reducing downtime and improving machine reliability. With solutions from Clouver, you can optimise your maintenance management by accurately predicting maintenance needs and thus extending your machines' lifespan.

Resource Optimisation

Technologies and methods for resource optimisation include analysing energy consumption and resource utilisation as well as implementing measures to reduce waste and costs. Application cases and benefits include improving resource efficiency and reducing operational costs. By using Industrial Internet of Things technologies, you can monitor and optimise the energy consumption of your production facilities to save costs and produce more environmentally friendly.

How Does Integration and Networking Work?

EtherCAT Protocols

EtherCAT protocols enable reliable and fast data transmission between machines and control systems. Benefits and challenges include improving process control and ensuring network security. Procom Automation integrates EtherCAT protocols into its systems to ensure seamless communication and high data transfer speed, making your production processes more efficient and reliable.

Industrial Communication Standards

Industrial communication standards like EtherCAT and OPC UA offer numerous benefits, including improving interoperability and supporting process optimisation and decision-making. Application cases include networking machines and control systems in industrial environments. By adhering to these standards, you can ensure that your Industrial Internet of Things systems communicate smoothly and work together optimally, leading to more efficient and flexible production.

Cybersecurity Aspects

Cybersecurity aspects are of great importance for the security and reliability of Industrial Internet of Things systems. Challenges and solutions include implementing firewalls and encryption technologies as well as setting up access controls and authentication mechanisms. Best practices include continuously monitoring network security and responding to security incidents. Clouver offers comprehensive cybersecurity solutions to protect your Industrial Internet of Things infrastructure and ensure that your data is protected from unauthorised access and cyber attacks.

Interoperability of Different Systems

The interoperability of different systems is crucial for the successful implementation of Industrial Internet of Things technologies. Technologies and methods to improve interoperability include using standardised communication protocols and integrating existing systems. Benefits and challenges include improving process control and reducing integration costs. With solutions from Procom Automation and Clouver, you can ensure that your different systems work together seamlessly and optimally support your production processes.

How Do You Practically Implement Industrial Internet of Things Technologies?

Best Practices for Implementation

Best practices for implementing Industrial Internet of Things technologies include conducting a pilot installation, training employees, and developing a clear implementation plan with milestones. Success factors include continuously evaluating progress and adjusting the plan as needed. Start small to gain initial experience and then gradually expand your Industrial Internet of Things infrastructure. With support from Clouver and Procom Automation, you can ensure that your implementation runs smoothly and you quickly benefit from the advantages.

Employee Qualification

Employee qualification is crucial for the successful implementation of Industrial Internet of Things technologies. Training and further education measures include imparting knowledge in dealing with Industrial Internet of Things technologies and developing skills for analysing and using data. Invest in regular training and workshops to ensure that your employees can effectively use the new systems and fully leverage the benefits of Industrial Internet of Things technologies.

Change Management

Change management includes methods and strategies for successfully implementing changes in the company. Challenges and solutions include employee acceptance and adapting processes and structures. Communicate the benefits of Industrial Internet of Things technologies clearly and support your employees during the change process. With a structured change management approach, you can overcome resistance and ensure sustainable integration of the new technologies.

ROI Considerations

ROI considerations include methods for calculating the return on investment (ROI) for implementing Industrial Internet of Things technologies. Examples and application cases include analysing costs and benefits as well as identifying optimisation potentials. Calculate the expected benefit of your Industrial Internet of Things investments by weighing the savings through increased efficiency, reduced downtimes, and improved product quality against the implementation costs. With solutions from Clouver and Procom Automation, you can ensure that your investments achieve a high ROI.

What Are the Future Trends?

AI Integration

The integration of Artificial Intelligence (AI) into Industrial Internet of Things systems offers numerous benefits, including improving data analysis and decision support. Application cases include predicting maintenance needs and optimising production processes. AI algorithms can analyse large data volumes and recognise patterns that escape human analysis, enabling you to make more precise and faster decisions. With Clouver, you can benefit from advanced AI solutions that further optimise your production processes.

Edge Computing

Edge computing enables data processing directly at the source, reducing latency times and improving efficiency. Benefits and challenges include improving process control and ensuring data security. By moving data processing closer to the devices, you can make real-time decisions and reduce network load. Procom Automation integrates edge computing solutions to make your production processes even more efficient.

Sergej Gigel

Senior Sales Manager

Have questions about the topic or want to learn more about our solutions?

Contact us and discover how our products can future-proof your machines. Let’s work together to find out how we can help take your production to the next level!

- +49 241 93681-500

- contact@procom-automation.de