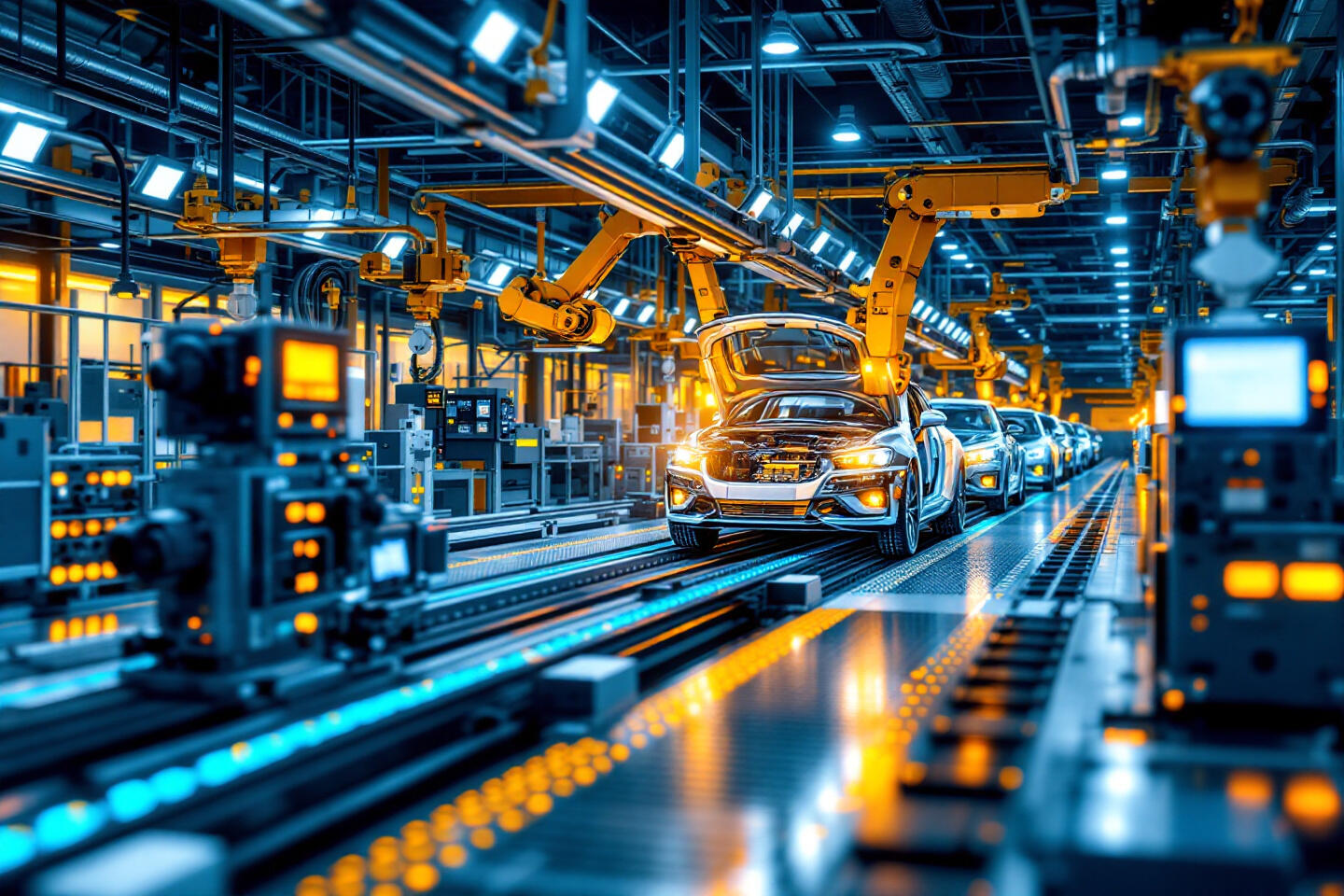

In today's manufacturing industry, production downtime is a costly and often avoidable issue that presents significant challenges for companies. Unplanned downtime can not only severely disrupt the production flow but also lead to substantial financial losses. But how can you minimise these downtimes and maximise your operation's efficiency?

In this post, we delve into the latest technologies and strategies that can help you reduce production downtimes. From Industrial Internet of Things (IIoT)-based monitoring to predictive maintenance and organisational optimisations—we show you how to detect and resolve bottlenecks early.

Discover how you can increase your machine availability and sustainably improve overall productivity through the use of modern analytical tools and proven methods. This post offers valuable insights and concrete action recommendations to optimise your production processes and stay competitive. Dive in and find out how you can effectively minimise production downtime!

How Does the Industrial Internet of Things (IIoT) Support Production Monitoring?

The Industrial Internet of Things (IIoT) connects machines, sensors, and systems to collect and analyse data in real-time. This technology is a key component of modern production monitoring, as it enables continuous monitoring of production processes. Through interconnectivity, potential problems can be immediately detected and resolved before they lead to major outages. With IIoT, you can not only monitor the current status of your machines but also analyse trends and initiate preventive actions.

One of the leading IIoT platforms is Clouver, offering comprehensive functionalities for production monitoring. Clouver allows you to collect and analyse all relevant data points in real-time, ensuring you always have an accurate overview of your production processes. This is crucial to avoid unnecessary downtime and maximise the efficiency of your manufacturing.

What Does Clouver Offer and How Does It Help You?

Clouver is a powerful IIoT-based platform specifically developed to monitor and analyse production data in real-time. Through seamless integration of machines, sensors, and ERP systems, Clouver provides a comprehensive overview of the condition and efficiency of your production.

Key features of Clouver include:

- Real-time Monitoring: Continuously track the status of your machines and production lines to respond immediately to deviations.

- AI-powered Fault Analysis: Use artificial intelligence to quickly identify errors and analyse their causes.

- Predictive Maintenance: Plan maintenance work based on current data and forecasts to prevent failures.

- Dynamic Dashboards: Visualise your production data clearly and adaptably to make informed decisions.

With Clouver, you can drastically reduce unplanned downtime and increase the availability of your machines, ultimately leading to higher overall productivity.

How Does Real-time Monitoring Work?

Real-time monitoring is crucial for continuously overseeing the production process and immediately responding to deviations. Through continuous data streams and second-by-second collection, you can monitor the status of your machines in real-time. All relevant parameters, such as temperature, pressure, and vibrations, are recorded and analysed.

Automatic notifications and dynamic dashboards from Clouver help you react instantly to critical conditions and avoid downtimes. This way, you can identify potential problems before they develop into major outages and take swift action to maintain the production flow.

How Does the Analysis of Overall Equipment Effectiveness (OEE) Help?

Overall Equipment Effectiveness (OEE) is a key metric for measuring the efficiency of your production facility. It consists of three components:

- Availability: The percentage of the planned production time that is actually utilised.

- Performance: The ratio between actual production speed and the maximum possible speed.

- Quality: The proportion of defect-free products in the total production.

By meticulously analysing OEE, you can identify weaknesses and bottlenecks in your production. Clouver offers tools to capture and evaluate these metrics so that you can take targeted optimisation actions. A high OEE indicates that your facility is operating efficiently with minimal downtime, directly contributing to an increase in overall productivity.

How Can You Optimise Mean Time to Repair (MTTR)?

Mean Time to Repair (MTTR) is the average time required to repair a machine after a failure. A high MTTR results in longer downtimes and greater production losses. By using real-time data analysis and AI-powered diagnostic tools from Clouver, you can significantly reduce MTTR.

Guided maintenance systems assist your technicians in quick and efficient fault resolution by providing precise instructions and step-by-step processes. Additionally, Clouver automatically documents the repair steps, enabling you to continuously learn from past mistakes and further optimise your repair processes.

Set New Standards in Production with ProCom!

Our high-tech control solutions are designed to maximise efficiency and precision in your production. Stay competitive and future-proof with our support. Contact us today to learn more about our technologies and achieve your goals!

What Is Predictive Maintenance and How Do You Benefit From It?

Predictive maintenance uses advanced AI algorithms to monitor the condition of your machines and predict potential failures. This allows you to perform maintenance work in a timely manner before an actual breakdown occurs. With Clouver, you can analyse historical data and identify patterns that indicate impending problems.

Optimised spare parts logistics and automated adjustments also help increase machine availability and minimise production downtimes. By taking timely maintenance actions, you can extend the lifespan of your machines and boost the overall productivity of your operation.

How Do Condition Monitoring Systems Help?

Condition monitoring systems continuously monitor the state of your machines and detect deviations early. By installing sensors and setting up alarms, you can react immediately to critical conditions and avoid downtime. Clouver seamlessly integrates these systems into your production environment, capturing and analysing all relevant data.

Condition monitoring allows you to monitor the exact condition of your machines at any time, enabling you to take preventive measures and reduce the likelihood of failures. This significantly contributes to enhancing your production efficiency and avoiding unnecessary downtime.

How Does Predictive Quality Control Work?

Predictive Quality Control utilises machine learning to foresee and prevent quality issues. By analysing production data, you can detect anomalies and take quality assurance measures before production failures occur. Clouver provides the necessary tools for conducting these analyses and proactively addressing quality issues.

By implementing predictive quality control, you ensure that your products always meet the highest quality standards, which not only increases customer satisfaction but also improves the efficiency of your production processes.

How Do Digital Twins Help Simulation?

Digital twins are virtual models of physical systems or processes. They enable the simulation and analysis of production processes in a digital environment, helping identify and resolve potential problems before they occur in real production. With Clouver, you can create digital twins and simulate various scenarios to determine the optimal operation of your machines.

Using digital twins allows you to test innovative solutions and optimisations without affecting the ongoing production process. This leads to more efficient production and significantly reduces the likelihood of downtime.

How Can You Apply Lean Manufacturing Principles?

Lean manufacturing aims to reduce waste and optimise processes. By implementing lean principles such as 5S (Sort, Set, Shine, Standardise, Sustain) and continuous improvement processes (Kaizen), you can make your production processes more efficient and lower the likelihood of downtimes.

Procom Automation supports you in successfully embedding these principles in your operation. With our expertise in CNC machines and cutting machines, we offer bespoke solutions to effectively implement lean manufacturing and sustainably enhance the efficiency of your production.

What Is Total Productive Maintenance (TPM)?

Total Productive Maintenance (TPM) encompasses preventive and predictive maintenance as well as regular training for employees on machine care. TPM teams from various departments develop comprehensive maintenance programs and measure the outcomes of TPM activities to increase machine availability.

By implementing TPM, you can establish a culture of continuous improvement and maintenance that helps minimise production downtimes and boost the efficiency of your operation.

How Do Standard Operating Procedures (SOPs) Help?

Standard Operating Procedures (SOPs) are detailed documentation of all production processes. Clear and understandable SOPs help your employees carry out processes efficiently and error-free. Procom Automation supports you in creating and implementing SOPs tailored to your production requirements.

Regular training and updates of SOPs help minimise production downtimes by ensuring that all employees always follow the latest best practices and avoid errors.

Conclusion

Minimising production downtimes is crucial for increasing overall productivity and efficiency in manufacturing. With Clouver, an IIoT-based platform, you can monitor and analyse production data in real-time. Through the connection of machines, sensors, and ERP systems, Clouver provides a comprehensive overview of the condition and efficiency of your production. Real-time monitoring, AI-powered fault analysis, and predictive maintenance are just some of the features that help reduce unplanned downtimes and increase machine availability.

Want to learn more about how Clouver can help you minimise production downtimes and boost the efficiency of your operation? Visit our post for more in-depth content or book a demo version of Clouver to experience the benefits yourself.

Sergej Gigel

Senior Sales Manager

Have questions about the topic or want to learn more about our solutions?

Contact us and discover how our products can future-proof your machines. Let’s work together to find out how we can help take your production to the next level!

- +49 241 93681-500

- contact@procom-automation.de