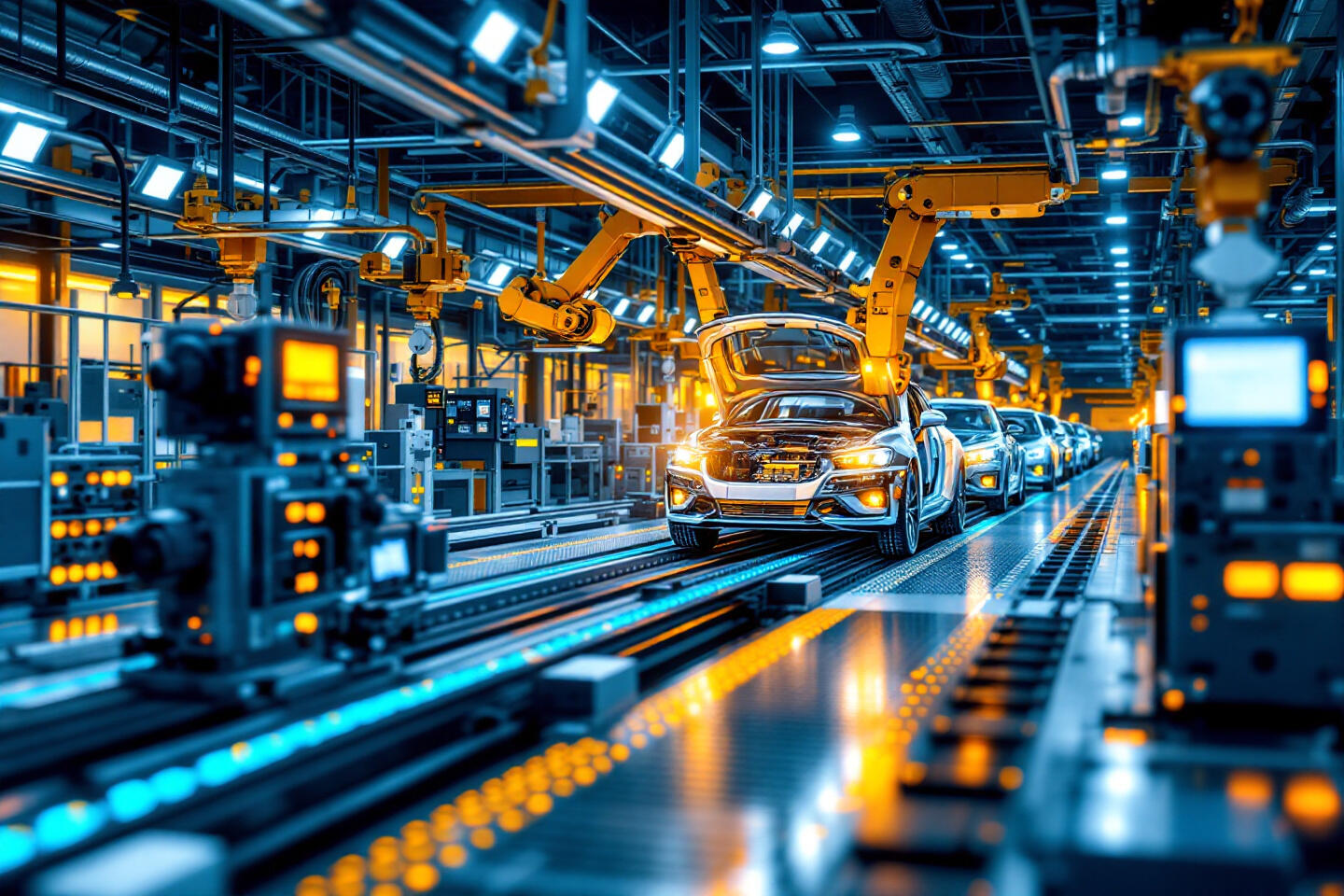

Why Remote Monitoring is Important for You

In today's fast-paced and digitalised world, monitoring production processes remotely is not just a trend but a necessity. The Industrial Internet of Things (IIoT) is revolutionising the way companies monitor and control their machines and production lines. With solutions like Clouver from ProCom Automation, you can access critical machine data in real-time, optimise production processes, and minimise downtime. Discover how Clouver helps you reduce your production costs, improve the quality of your products, and gain a significant competitive advantage.

What is the Industrial Internet of Things (IIoT)?

The Industrial Internet of Things (IIoT) refers to the networking of machines, devices, and sensors in industrial environments to collect, evaluate, and optimise processes based on the gathered data. ProCom Automation is a leader in this field and offers a comprehensive solution with Clouver, enabling you to drive the digital transformation in your company. IIoT is essential for the industry as it forms the basis for more efficient, transparent, and flexible production. Continuous data collection allows you to monitor your production processes, identify bottlenecks, and take proactive measures for improvement, ultimately increasing your competitiveness. Learn more about IIoT devices in the industry.

How Does Remote Monitoring Work?

Remote monitoring refers to the use of networked technologies to monitor machines and production processes from a distance. With Clouver from ProCom Automation, you can access machine data in real-time without having to be physically present on-site. This offers numerous advantages: you can track the current status of your machines anytime and anywhere, detect potential problems early, and prevent unplanned downtime. Additionally, you can optimise production processes through data-driven decisions and identify improvement opportunities, ultimately reducing maintenance costs and extending the lifespan of your machines. More on the benefits of remote monitoring.

How Does Clouver Assist You with Monitoring?

Clouver is the advanced IIoT solution from ProCom Automation that offers real-time monitoring and comprehensive data analysis for your production processes. The main functions of Clouver include the collection and processing of real-time data, seamless integration into existing CNC systems, and customisable dashboards that provide a quick overview of key machine data. With Clouver, you get a central platform that collects, processes, and helps you make informed decisions to optimise your production processes. More details can be found in our IIoT Monitoring Software Clouver Maintenance.

How Does Real-Time Monitoring with Clouver Work?

With Clouver, you can monitor the current status and performance of your machines in real-time. This enables you to react immediately to deviations or anomalies. For example, you can keep a close watch on cutting processes like laser, waterjet, and plasma cutting. Clouver captures crucial metrics such as cutting speed, temperature, and material consumption, so you always know whether the process is running optimally or if adjustments are needed. Through this detailed monitoring, you can maximise the efficiency of your production processes while ensuring the quality of your products. More information on process monitoring in manufacturing.

How to Integrate Clouver into Existing CNC Systems?

Integrating Clouver into your existing CNC control systems from ProCom Automation is straightforward and seamless. The process involves compatibility checks, using Clouver's interfaces, and configuring the dashboards. This integration ensures that all relevant data is captured and processed without needing to modify your existing systems. ProCom Automation supports you in making the integration process efficient and smooth. More information can be found on our CNC control systems page.

How Secure is the Data Collection and Transmission with Clouver?

Data security is of utmost importance for IIoT solutions. Clouver from ProCom Automation ensures that your machine data is securely collected and transmitted. This is achieved through encrypted communication protocols, the implementation of firewalls and VPNs, and continuous network security monitoring. These measures ensure the integrity and confidentiality of your data, so you can rely on a secure and reliable monitoring of your production processes. Learn more about security in IIoT.

What Interfaces Does Clouver Offer for CNC Control Systems?

Clouver offers a variety of interfaces and protocols that enable seamless integration into various CNC control systems from ProCom Automation. This includes standardised protocols such as OPC UA, MQTT, and REST APIs, as well as flexible configuration options. Numerous companies have successfully integrated Clouver into their existing CNC systems and benefit from seamless data flows and improved process control. This comprehensive support for interfaces ensures that integration is quick and efficient, allowing you to immediately benefit from real-time data monitoring. More details on CNC machines and integration.

How to Use Clouver Dashboards for Machine Data?

Clouver's dashboards provide an intuitive and user-friendly interface for visualising your machine data. Features and benefits include real-time data visualisation, customisation of the dashboards according to your specific requirements, and the presentation of key data points, so you can quickly respond to deviations. These dashboards enable you to instantly recognise the performance of your machines and make informed decisions to optimise your production processes. With Clouver, you always have all essential information at a glance and can continuously improve your production quality and efficiency.

Boost Your Productivity with Clouver!

With our powerful IIoT platform, you'll have complete control over your production processes at all times. Reduce downtime, optimise resource usage, and stay ahead of your competition. Schedule your personal consultation now and discover how Clouver can support you!

How to Avoid Technical Disruptions with Clouver?

To ensure the reliability of Clouver, it is essential to avoid technical errors such as URL parameter errors. This can be achieved by correctly formatting URL parameters, conducting regular tests and maintenance, and implementing best practices for error prevention. By taking these precautions, you ensure that Clouver always functions reliably and that your production processes are not disrupted by technical issues.

How to Monitor Cutting Processes with Clouver?

With Clouver, you can monitor various cutting processes such as laser, waterjet, and plasma cutting in real-time. Each cutting process has specific requirements that Clouver supports optimally. The detailed monitoring allows you to maximise the efficiency and quality of your cutting processes. Real-time data analysis enables you to make immediate adjustments to ensure optimal cutting conditions and minimise material waste. Additionally, Clouver helps you detect potential issues early and plan maintenance accordingly, extending the lifespan of your cutting machines. More on the different cutting processes.

How Does Machine Condition Monitoring with Clouver Work?

Monitoring the condition of machines is crucial for the maintenance and smooth operation of your production facilities. Clouver offers advanced methods for condition monitoring, including the collection and analysis of machine data, early detection of problems, and planning preventive measures. Continuous condition monitoring enables you to extend the lifespan of your machines, reduce maintenance costs, and increase overall productivity. Clouver allows you to always keep an eye on the condition of your machines and react proactively to changes. More information on machine condition monitoring.

How to Analyse Production Data with Clouver?

Analysing production data is essential to identify optimisation potentials in your production processes. With Clouver, you benefit from powerful analysis tools that help you collect and process extensive production data, recognise patterns and trends, and make processes more efficient. Detailed production data analysis enables you to make data-driven decisions that lead to continuous improvement of your production processes. Clouver supports you in identifying and implementing the right measures to increase efficiency and reduce waste. Learn more about production data analysis.

How to Implement Predictive Maintenance with Clouver?

Predictive Maintenance is a modern maintenance strategy that relies on analysing machine data to perform maintenance work before problems occur. With Clouver, you can effectively implement Predictive Maintenance by analysing data-driven predictions, planning maintenance work, and reducing maintenance costs through targeted and timely actions. Implementing Predictive Maintenance with Clouver can increase the reliability of your machines, extend their lifespan, and lower the overall costs of your production processes. This proactive maintenance strategy significantly contributes to increasing efficiency and minimising operational interruptions. More on Predictive Maintenance.

How Does Clouver Increase Your Production Efficiency?

Real-time monitoring with Clouver significantly contributes to increasing the efficiency of your production processes. Continuous monitoring enables you to immediately identify bottlenecks and inefficiencies and take measures for optimisation. Practical examples show how companies have optimised their production workflows, shortened lead times, and increased overall productivity by using Clouver. Real-time monitoring also allows more precise control of production processes, leading to higher machine utilisation and better resource use. Learn more about increasing efficiency through IIoT.

How Does Clouver Reduce Your Costs Through Preventive Maintenance?

Preventive maintenance with Clouver offers significant cost-saving potential by avoiding unplanned downtime and reducing maintenance expenses. Early detection of wear and potential issues allows you to perform targeted maintenance actions before costly repairs or production stoppages occur. Practical examples show how companies have significantly reduced their operating costs and maximised their machine uptime by implementing Clouver and preventive maintenance. More on preventive maintenance.

How Does Clouver Improve the Quality of Your Products?

The transparency of machine data is crucial for effective quality control. With Clouver, you can view and analyse all relevant data at a glance, allowing more precise monitoring and control of production processes. This leads to more consistent product quality, as deviations can be detected and corrected immediately. Practical examples show how companies have achieved significant improvements in product quality by using Clouver and making data-driven decisions to optimise production parameters. Learn more about quality improvement through IIoT.

What Competitive Advantages Does Clouver Offer You?

Digital transformation, supported by solutions like Clouver from ProCom Automation, provides your company with significant competitive advantages. By optimising production processes, increasing efficiency, and improving product quality, you can stand out significantly from your competitors. Success stories from companies demonstrate how integrating Clouver into their production environment has led to sustainable increases in competitiveness. Additionally, digital transformation enables faster adaptation to market changes and technological developments, securing your company's long-term success. More on digital transformation in the industry.

Conclusion: Why You Should Use Clouver

Remote monitoring in the realm of the Industrial Internet of Things (IIoT) offers numerous benefits for the manufacturing industry. Continuous real-time monitoring of machines and processes allows you to detect potential problems early, improve efficiency, and reduce operational costs. Integrating IIoT solutions like Clouver from ProCom Automation enables you to make data-driven decisions, increase transparency, and maximise production performance. Make your IIoT environment secure and future-proof! Discover how Clouver helps you minimise risks and maximise efficiency. Together, we find the right solution for your company. Visit our post for more information or schedule a demo version of Clouver.

Sergej Gigel

Senior Sales Manager

Have questions about the topic or want to learn more about our solutions?

Contact us and discover how our products can future-proof your machines. Let’s work together to find out how we can help take your production to the next level!

- +49 241 93681-500

- contact@procom-automation.de