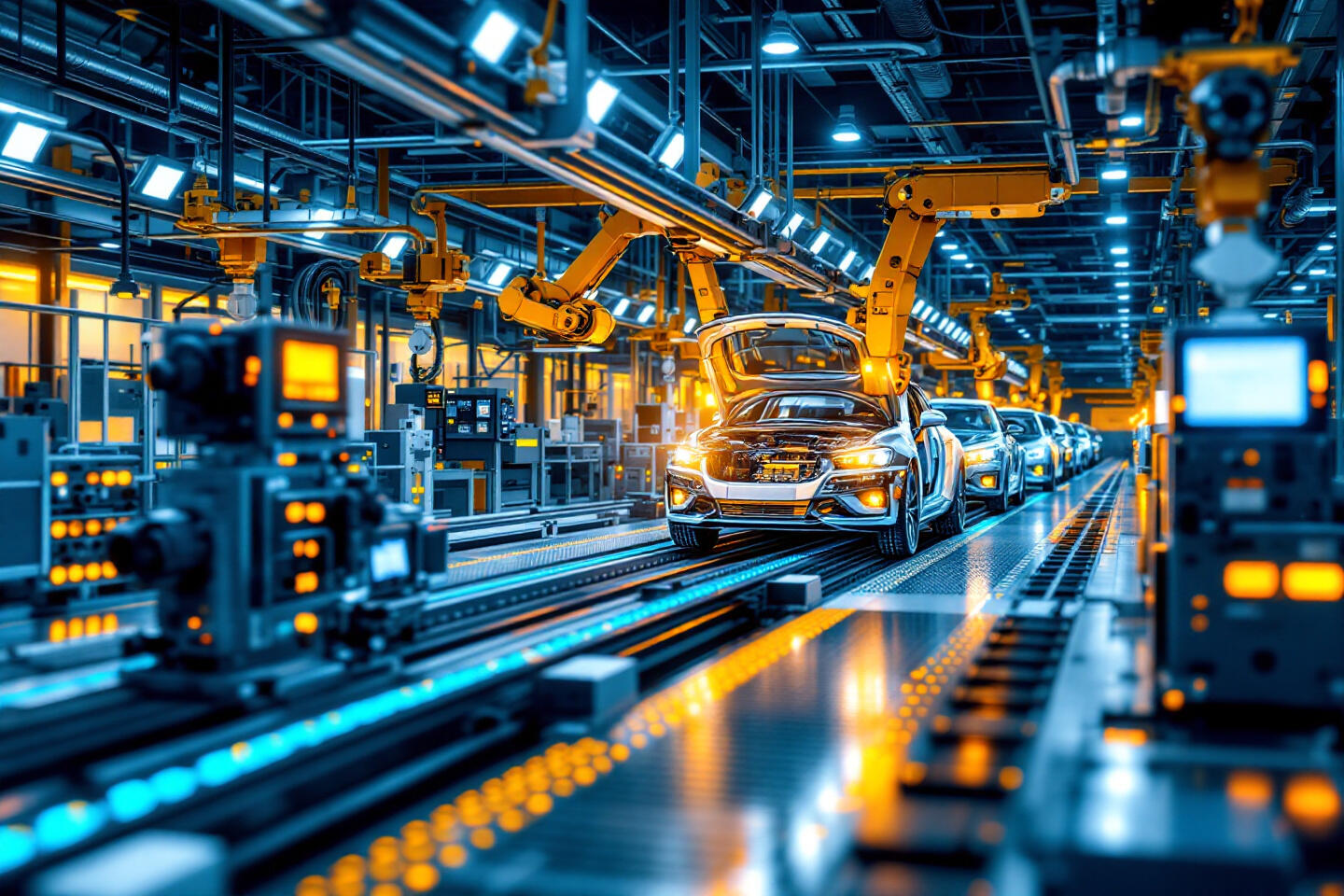

Introduction: Why is training in the Smart Factory so important?

In a world increasingly shaped by digitalisation and automation, the Smart Factory is becoming the heart of modern production processes. But how can you, as a specialist or company, stay up-to-date with these rapid developments? The answer lies in targeted training in the field of Smart Factory.

Have you ever wondered how to make your production systems more efficient or reduce unplanned downtime? Or how to best prepare your employees for the challenges of Industry 4.0? This post provides you with the answers and shows concrete ways on how to master the transition to the Smart Factory successfully through targeted training. Benefit from practical tips, best practices, and a comprehensive overview of the latest technologies and trends. Get inspired and start your journey into the future of production today!

What is a Smart Factory and why is it important?

Definition and significance of the Smart Factory

A Smart Factory is a highly automated and connected production environment that utilises the latest technologies such as the Industrial Internet of Things (IIoT), Artificial Intelligence (AI), and Big Data to optimise and make production processes more efficient. These technologies enable flexible and adaptable production that can quickly respond to market changes and customer demands. In the Smart Factory, machines, systems, and people are seamlessly connected, resulting in continuous improvement of production processes and increased competitiveness.

What are the advantages and challenges of the Smart Factory?

The benefits of the Smart Factory are manifold: you benefit from increased efficiency, reduced costs, improved product quality, and faster response times to market changes. Through real-time monitoring of production processes, you can identify bottlenecks early and react flexibly. Furthermore, the Smart Factory enables more precise planning and control, which increases overall productivity.

However, there are also challenges that need to be overcome. Integrating new technologies into existing systems can be complex and costly. Additionally, the successful implementation of the Smart Factory requires comprehensive qualification of employees so they can effectively use the new systems. Another crucial aspect is ensuring data security to protect sensitive production data from cyber-attacks. These challenges, however, can be successfully managed through targeted training and strategic planning.

What technological foundations are essential for the Smart Factory?

How do Industrial Internet of Things (IIoT) systems like Clouver help?

Industrial Internet of Things (IIoT) systems like Clouver play a central role in the Smart Factory. Clouver enables the networking and monitoring of machines and systems in real-time, leading to improved overall equipment effectiveness (OEE) and a reduction in mean time to repair (MTTR). By analysing real-time data, you can continuously optimise production processes and react early to potential problems. Clouver offers a user-friendly interface for visualising production data and supports you in making informed decisions to increase efficiency.

Why is data collection and analysis so important?

Collecting and analysing production data is crucial for optimising processes. Sensors collect a variety of data points, such as temperature, pressure, vibrations, and production volume. This data is collected in real-time and evaluated using advanced analysis tools to identify patterns and trends. Detailed data analysis allows you to identify bottlenecks, determine the causes of production errors, and take targeted measures to improve processes. This results in higher product quality and smoother production flow.

What role do automation technologies play?

Automation technologies such as robots and CNC control systems from ProCom Automation increase efficiency and precision in production. These technologies take over repetitive tasks, reducing processing times and defects. With the advanced CNC control systems from ProCom Automation, you can perform complex machining processes with the highest precision, improving product quality and minimising material consumption. Automation allows your employees to focus on value-added activities, increasing overall productivity of your company.

How important are sensors and measurement technology?

Sensors and measurement technology are the eyes and ears of the Smart Factory. They gather essential data on the condition of machines and processes, such as temperature, pressure, vibrations, and flow rates. This data is used to enable predictive maintenance and monitor product quality. By integrating high-quality sensors from ProCom Automation, you can monitor the condition of your machines in real-time and carry out maintenance work precisely when needed. This reduces unplanned downtime and significantly extends the life of your equipment.

Get the Best Out of Your Production with Clouver!

Connect your machines and gain valuable insights into your production processes. Reduce unused capacity, optimise resource utilisation, and increase your revenue. Contact us today for a no-obligation consultation!

What training formats are available?

How do online courses and e-learning help?

Online courses and e-learning platforms offer you a flexible way to further your education in the field of Smart Factory. You can learn anytime and anywhere, which is particularly beneficial if you are employed or prefer individual learning times. These platforms offer a wide range of courses, from basic concepts to advanced topics. Interactive content and practical exercises allow you to effectively deepen your knowledge and apply it directly in your work environment.

What do in-person training sessions offer?

In-person training sessions offer the advantage of direct interaction with experts and practical experience. These trainings are particularly suitable for complex topics that require intensive supervision and immediate feedback. In ProCom Automation's in-person training sessions, you have the opportunity to experience the latest CNC control systems and automation technologies live and to apply them practically under expert guidance. This promotes a deeper understanding and facilitates the implementation of what you have learned in your company.

What is blended learning?

Blended Learning combines the advantages of online courses and in-person training. This hybrid form of learning allows you flexible yet intensive further training. You can work through theoretical content online at your own pace and deepen what you have learned in practical in-person events. Blended Learning offers an optimal balance between flexible learning times and direct exchange with experts and other participants, significantly accelerating the learning curve.

Why are manufacturer certifications important?

Manufacturer certifications officially confirm your acquired knowledge and skills. They are a valuable tool to prove your qualifications and improve your career chances. Certifications from ProCom Automation and Clouver are particularly well-regarded and underline your expertise in the field of Smart Factory. By completing these certification programs, you show potential employers and business partners that you possess the necessary know-how to effectively use and manage modern production systems.

What do practical workshops offer?

Practical workshops offer you the opportunity to apply what you have learned directly and gain practical experience. These workshops are particularly valuable for deepening specific topics and solving real production problems. In ProCom Automation's practical workshops, you have the chance to work with the latest CNC machines and automation technologies and test your skills in a realistic environment. This promotes practical understanding and the ability to efficiently transfer theoretical knowledge into practice.

What are the main focus areas in training?

How do you optimise production processes?

Methods and techniques for optimising production processes are a central part of the training. You learn how to analyse production workflows, identify inefficient areas, and implement targeted improvement measures. Case studies and best practices provide valuable insights into successful optimisation projects and help you apply proven methods in your own company. By applying these techniques, you can significantly increase the efficiency of your production while simultaneously reducing costs.

How do you automate processes?

Automating processes significantly increases efficiency and productivity. You learn how to replace manual and repetitive tasks with automated systems, shortening processing times and reducing defect rates. Practical exercises and simulations help you apply theoretical knowledge and understand the functioning of automation technologies. With ProCom Automation's automation solutions, you can precisely control and optimise complex production processes, resulting in higher product quality and increased overall productivity.

What is predictive maintenance?

Predictive maintenance enables proactive planning of maintenance work before failures occur. You learn how to analyse production data to determine the optimal time for maintenance work and minimise unplanned downtime. By using Industrial Internet of Things (IIoT) systems like Clouver, you can continuously monitor the condition of your machines and detect potential problems early. This increases the availability of your equipment and sustainably extends its lifespan. Find out more in our article on predictive maintenance.

Why are data analysis and visualisation important?

The ability to analyse and visualise data is crucial for optimising production processes. You learn how to efficiently process large amounts of data and extract relevant information. Advanced knowledge in this area enables you to make informed decisions to improve processes. With tools from Clouver, you can clearly present complex production data and make quick, data-driven decisions that significantly increase the efficiency and quality of your production.

How do you ensure quality?

Quality assurance processes are essential for meeting standards and satisfying your customers. You learn how to implement, monitor, and continuously improve quality controls. Implementing and monitoring these processes is a major focus of training, as they directly affect product quality and customer satisfaction. By using sensors and measurement technology from ProCom Automation, you can perform precise quality controls and ensure that your products always meet the highest standards.

What management aspects are important?

How do you implement changes successfully?

Successfully implementing changes requires effective change management. You learn strategies and methods to steer and accompany change within your company. This includes communicating change goals, involving employees, and overcoming resistance. Effective change management is crucial for smoothly and successfully implementing Smart Factory technologies.

How do you qualify your employees?

Qualifying employees is crucial for the success of the Smart Factory. You develop programs for employee qualification to ensure your team has the necessary knowledge and skills to effectively use and manage modern production systems. Targeted training measures can boost motivation and performance of your employees while also enhancing the innovative strength of your company.

How do you measure the ROI of training measures?

The return on investment (ROI) of training measures must be measured and evaluated to quantify and justify the benefits of training. You learn how to analyse and present the costs and benefits of training programs. This helps you make informed decisions about investments in training and clearly communicate the added value to your company.

How do you integrate new technologies?

Strategies for implementing Smart Factory technologies are crucial for success. You learn how to effectively integrate new technologies into existing processes while keeping operations running smoothly. These strategies include planning, execution, and follow-up of implementation steps as well as continuous optimisation of the new systems.

How do you develop your personnel long-term?

Long-term personnel development ensures your team stays current with technological developments. You plan the training and development of your employees to continuously expand and adapt their skills. This is crucial for the sustainable competitiveness of your company and the successful utilisation of Smart Factory technologies.

Conclusion: Start your journey into the future of production

Training for the Smart Factory offers immense benefits for modern production. By integrating Industrial Internet of Things (IIoT) solutions like Clouver, you can monitor and analyse production processes in real-time, leading to improved overall equipment effectiveness (OEE) and a reduction in mean time to repair (MTTR). This enables companies to identify bottlenecks early, minimise downtime, and sustainably increase overall productivity.

Take the opportunity to future-proof your production by considering innovative automation solutions from ProCom Automation. Experience how our customised CNC control systems can maximise your efficiency and precision. Schedule a free demo of Clouver now or contact us for personalised advice to learn more about our solutions. Visit our blog for more in-depth content and stay informed about the latest developments in the Smart Factory world!

Sergej Gigel

Senior Sales Manager

Have questions about the topic or want to learn more about our solutions?

Contact us and discover how our products can future-proof your machines. Let’s work together to find out how we can help take your production to the next level!

- +49 241 93681-500

- contact@procom-automation.de