In the modern manufacturing industry, you may face the challenge of choosing the optimal production method for your specific requirements. The decision between additive and conventional manufacturing raises numerous questions: Which technology offers the best economic benefits? How do the methods differ in terms of material properties and process integration? And what developments and trends should you consider?

Introduction to Manufacturing Methods

What is Additive and Conventional Manufacturing?

Additive manufacturing, often referred to as 3D printing, is an innovative process in which material is added layer by layer to create an object. This method enables the production of complex geometries and customized products that are difficult to achieve with traditional methods. You can use various additive technologies such as FDM (Fused Deposition Modeling), SLA (Stereolithography), and SLS (Selective Laser Sintering) depending on your project's requirements.

Conventional manufacturing includes proven methods like milling, turning, and casting, where material is removed through cutting or forming to achieve the desired shape. These methods have been established since the industrial revolution and are widely used, particularly in mass production. Conventional methods offer high production speeds and precision, making them ideal for standardized and large-volume productions.

How Have Manufacturing Methods Evolved?

Additive manufacturing has made significant strides over the past decades, especially since the introduction of the first 3D printing technologies in the 1980s. Originally developed for prototyping and small series production, its scope has since expanded to numerous industries, including aerospace, medicine, and the automotive industry. Milestones include the development of metals in 3D printing and improvements in printing speed and accuracy.

In contrast, conventional manufacturing has a long history dating back to the industrial revolution. Technological advancements such as CNC machining (Computer Numerical Control) have significantly increased the precision and efficiency of these processes. Historical milestones include the introduction of automated machines and the development of materials specifically optimized for certain manufacturing processes.

What is the Significance of These Methods in Modern Industry?

Both manufacturing methods play a crucial role in modern industry. Additive manufacturing offers flexibility and efficiency in producing complex and customized parts, which is particularly important in industries that require individual solutions. At the same time, conventional manufacturing impresses with its high production speed and precision, making it ideal for mass production of standardized products. Choosing the right method can significantly contribute to your company's competitiveness.

Technological Fundamentals

How Do the Manufacturing Methods Work?

Additive manufacturing is based on the layer construction process, where material is applied layer by layer to create a three-dimensional object. Common additive methods include FDM (Fused Deposition Modeling), SLA (Stereolithography), and SLS (Selective Laser Sintering). These technologies allow for high precision and detail accuracy, which is particularly advantageous for complex and customized parts.

Conventional manufacturing involves subtractive processes, where material is removed by cutting, drilling, or milling to achieve the desired shape. Common conventional methods include CNC machining, injection moulding, and forging. These processes are particularly efficient for producing large quantities and offer high dimensional accuracy and surface quality.

What Materials Are Used?

Additive manufacturing supports a variety of materials, including plastics, metals, ceramics, and biomaterials. The choice of material strongly depends on the specific application and desired properties of the end product. New materials are continuously being developed to enhance the performance of additive manufacturing.

Conventional manufacturing also utilizes a wide range of materials, varying depending on the process and end product. These include steels and alloys, plastics, cast metals, and composites. These materials are often specifically optimized for the respective machining to achieve the best possible results.

How Are Processes Controlled?

Additive manufacturing requires precise control over various technical parameters such as layer height, printing speed, and temperature. Process control is often digital, enabling high precision and repeatability. Modern software solutions like Clouver offer advanced Industrial Internet of Things and production monitoring functionalities to monitor and optimize the printing process in real-time.

Conventional manufacturing relies on the precise control of parameters such as cutting speed, feed rate, and cooling. Control is usually carried out via CNC machines from ProCom Automation, known for their precision and efficiency. These machines allow detailed process control and are essential for producing high-quality products.

Economic Aspects

How Do the Costs Differ?

Additive manufacturing can initially cause high investment costs for 3D printers. However, operating costs are often lower, as less material is wasted, and maintenance costs are lower due to fewer moving parts in the machines. For small series and individual products, additive manufacturing can be more cost-efficient as expensive tool changes are not required.

Conventional manufacturing often has lower machine costs compared to 3D printers. However, operating costs can increase due to high material consumption and the need for regular tool changes. Maintenance costs are also higher, as conventional machines are more complex and have more moving parts. However, in mass production, the unit costs decrease significantly once the initial tooling costs are spread over many units.

How Scalable Are the Methods?

Additive manufacturing is particularly well-suited for small series and prototyping, as production costs remain relatively constant regardless of the quantity. This allows you to react flexibly to market demands and quickly make adjustments.

Conventional manufacturing is more efficient for mass production as unit costs decrease with increasing quantity. This makes it ideal for producing large quantities of standardized parts where high production speeds and low unit costs are crucial.

How Energy-Efficient Are the Methods?

Additive manufacturing tends to be more energy-efficient and produces less material waste, as only the required material is used. This contributes to reducing the ecological footprint and can be further optimized in combination with sustainable materials.

Conventional manufacturing has a higher energy consumption and produces more material waste through subtractive processes. However, energy consumption and waste can be reduced through optimizations and recycling measures. Advances in machine control and material science also contribute to improving energy efficiency.

Quality and Performance

How Accurate and High-Quality Are the Products?

Additive manufacturing offers improved dimensional accuracy and surface quality through calibration and post-processing. However, these values often do not quite reach the level of conventional methods. For many applications, however, the accuracy and surface quality are sufficient, especially for complex and customized parts.

Conventional manufacturing generally offers higher dimensional accuracy and surface quality through precise tools and optimized machining processes. This is particularly important for applications that require high tolerances and smooth surfaces, such as in the automotive and medical industries.

What Are the Mechanical Properties Like?

Additive manufacturing allows for adjusting mechanical properties through the choice of material and adjusting printing parameters. Nevertheless, the mechanical properties often do not reach the maturity and strength of conventionally manufactured parts. For many applications, however, the differences are negligible, especially when it comes to complex structures and lightweight components.

Conventional manufacturing generally offers better mechanical properties as the materials are solid and proven machining methods are used. This is crucial for applications that require high strength, hardness, and durability.

How Reproducible Are the Methods?

Additive manufacturing achieves high reproducibility through standardized processes and digital control. This ensures that every produced part meets the same specifications, particularly benefiting serial productions.

Conventional manufacturing also offers high reproducibility, especially in mass production. Precise tools and machines ensure that each part is consistently produced, which is of great importance for quality assurance.

How Is Quality Monitored?

Additive manufacturing enables real-time monitoring and in-process monitoring to ensure quality during the printing process. Modern software solutions like Clouver offer advanced monitoring functions that can detect errors early and optimize production.

Conventional manufacturing uses established quality controls and inspections that provide high security and reliability. By utilizing ProCom Automation and their precise machines, you can ensure that production standards are always met.

Your Partner for Innovative Automation Solutions!

ProCom offers the perfect combination of intelligent software, premium hardware, and comprehensive support. Whether knife, laser, or waterjet cutting – we'll develop the ideal solution for your production needs. Arrange your consultation today and get started!

Process Integration

How Are Digital Workflows Integrated?

Additive manufacturing seamlessly integrates digital workflows from CAD modelling to manufacturing. This allows for efficient and flexible production where digital models can be directly converted into physical objects. Software solutions like Clouver support this process through comprehensive data integration and automation.

Conventional manufacturing also uses CAD/CAM systems to integrate into the manufacturing process. These systems increase efficiency and precision by converting digital models directly into machine commands. Integration into existing systems is often well-established and supported by ProCom Automation's precise CNC machines.

What Is the Automation Potential?

Additive manufacturing offers high automation potential, for example through the use of robotic arms for material handling and post-processing. This increases production capacity and reduces the need for manual intervention, improving efficiency.

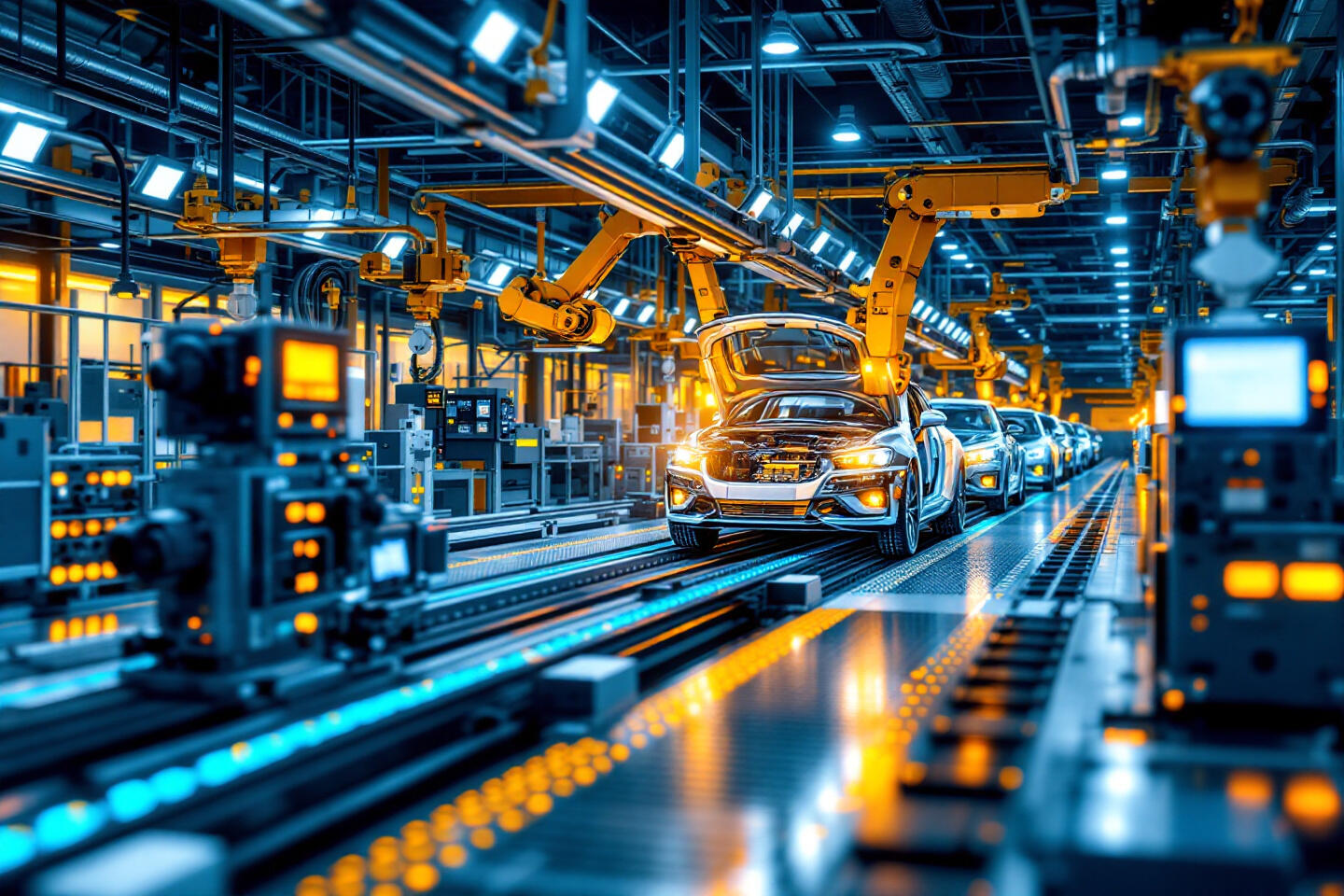

Conventional manufacturing also has significant automation potential, particularly in CNC machining and assembly. Automated systems can undertake repetitive tasks, increase production speed, and minimize error rates. ProCom Automation offers advanced solutions to support and optimize this automation.

How Compatible Are the Methods with Industry 4.0?

Additive manufacturing plays an important role in Industry 4.0, as Industrial Internet of Things and connected systems can optimize and monitor processes. The integration of smart sensors and data analysis enables real-time monitoring and adjustment of production processes, further increasing efficiency and quality.

Conventional manufacturing can also be seamlessly integrated into an Industry 4.0 environment. By using connected machines and data-driven process control, the efficiency and flexibility of production lines can be improved. ProCom Automation and Clouver offer tailored solutions to support the digital transformation of your manufacturing.

How Are the Methods Integrated into Existing Production Lines?

Additive manufacturing can be integrated into existing production lines, though it often requires adjustments and training. Implementing 3D printing technologies can increase the flexibility and adaptability of your production lines, allowing you to respond to market changes more quickly.

Conventional manufacturing enables relatively easy integration of new machines into existing lines, as the methods are well-established. New CNC machines from ProCom Automation can be seamlessly added to existing systems to increase production capacity and quality without requiring extensive changes.

Industry-Specific Comparisons

In Which Industries Are the Methods Used?

Additive manufacturing is particularly advantageous in industries such as aerospace, medical technology, and the automotive industry. Here, complex and customized parts are required that are difficult to achieve with conventional methods. For example, custom-fitted implants in medical technology enable better fit and functionality.

Conventional manufacturing is widespread in mechanical engineering, electronics, and the consumer goods industry. These industries benefit from the mass production of standardized parts that require high precision and consistency. In the automotive industry, for instance, conventional methods are essential for producing large quantities of identical components.

How Do Prototyping and Series Production Differ?

Additive manufacturing is ideal for rapid prototyping and small series production. Changes can be implemented quickly and cost-effectively, reducing development time and increasing flexibility. This is particularly useful in the product development phase, where rapid iterations are required.

Conventional manufacturing is more efficient and cost-effective for mass production. Once the tools are set up, large quantities can be produced at low cost. This is particularly beneficial when you want to quickly bring a product with stable demand to market.

How Are Complex Geometries Manufactured?

Additive manufacturing allows for the creation of complex geometries that are difficult or impossible to achieve with conventional methods. Structures such as internal cavities, organic shapes, and intricate details can be easily created, enabling innovative designs and functional improvements.

Conventional manufacturing faces challenges in producing complex shapes. Although special tools and techniques such as multi-axis milling and precision casting can meet many requirements, they are often more expensive and time-consuming than additive methods. Nevertheless, there are ways to realise complex designs through the use of modular tools and intelligent manufacturing strategies.

What About Customisation?

Additive manufacturing offers excellent customisation and personalisation possibilities for products. Each part can be uniquely designed without additional costs for tool changes. This is particularly valuable in medical technology, the fashion industry, and custom consumer goods.

Conventional manufacturing does allow for customisation, but it is often associated with higher costs and longer production times. Every change may require new tools or adjustments to existing machines, making the process less flexible and more expensive.

Conclusion: Which Manufacturing Method Is Right for You?

In conclusion, both additive and conventional manufacturing have their strengths and weaknesses. While additive manufacturing excels in flexibility, material efficiency, and the ability to create complex geometries, conventional manufacturing shines with high production speeds and proven precision in mass production. Choosing between these approaches strongly depends on your project's specific requirements and desired outcomes.

If you want to learn more about optimising your manufacturing processes, we invite you to book a demo version of Clouver. ProCom Automation offers advanced solutions for process monitoring, error detection, and predictive maintenance that can take your production to the next level. Learn more at ProCom Automation and discover how we can help you increase the efficiency and quality of your manufacturing.

Sergej Gigel

Senior Sales Manager

Have questions about the topic or want to learn more about our solutions?

Contact us and discover how our products can future-proof your machines. Let’s work together to find out how we can help take your production to the next level!

- +49 241 93681-500

- contact@procom-automation.de