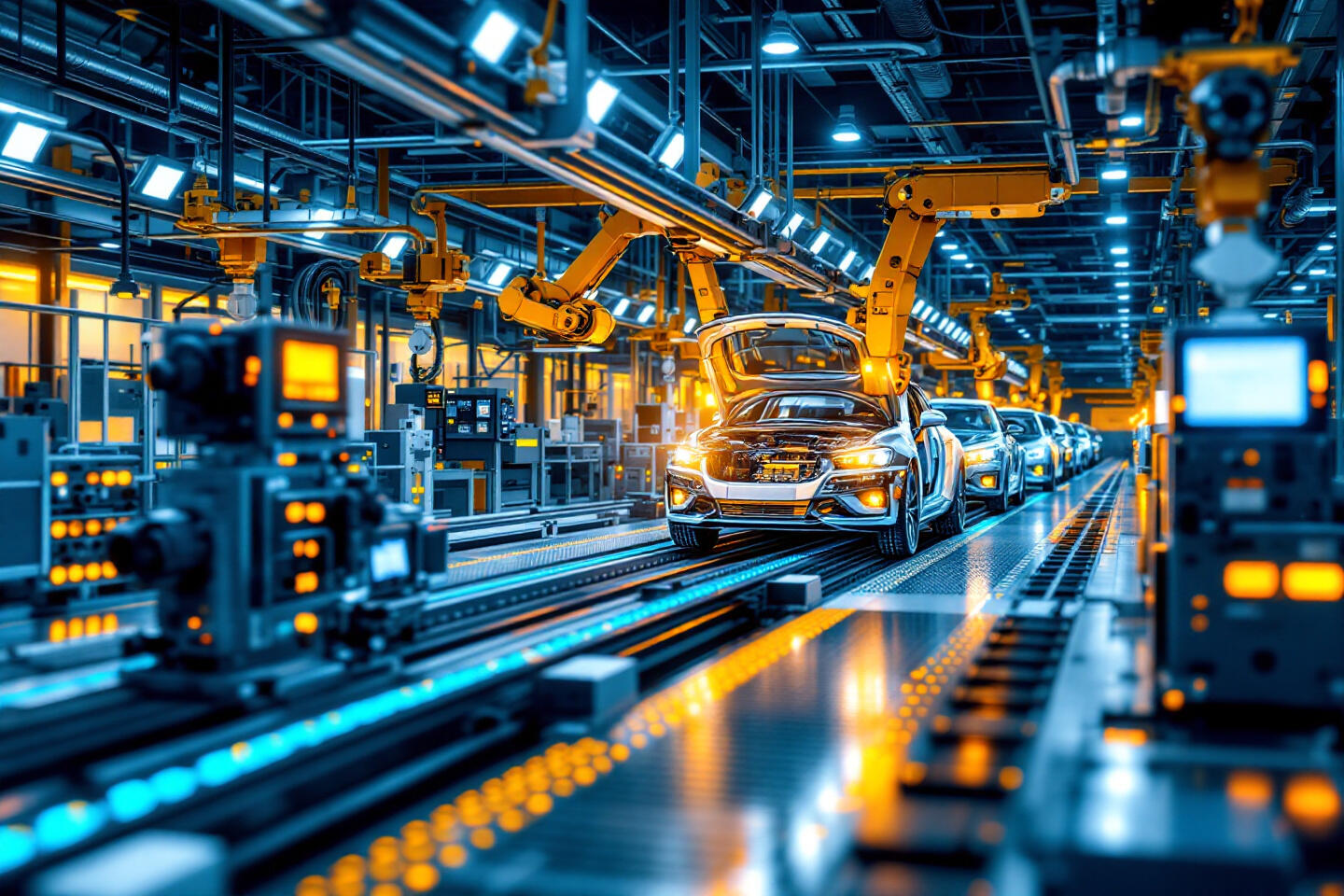

In today's fast-paced and technology-driven world, businesses face the challenge of making their production processes more efficient and smarter. This is where the Industrial Internet of Things (IIoT) comes into play. But what exactly is an IIoT platform, and why is it so crucial for modern industry? In this post, we answer these questions and delve deep into the world of IIoT platforms. You will learn how they work, what components they include, and the benefits they offer. Whether you are an industry expert looking for new ways to boost productivity or a tech enthusiast keen to learn more about the latest trends, this post provides valuable insights and practical information. Discover how IIoT platforms are shaping the future of industrial automation and data analysis, and what specific applications and benefits they can provide for your business.

Introduction to IIoT and IIoT Platforms

What does IIoT mean?

The Industrial Internet of Things refers to the networking of machines and devices in the industrial sector to collect and analyse extensive data. This networking enables you to optimise processes, increase efficiency, and reduce downtime. Imagine your CNC machines from Procom Automation are constantly connected to the internet, sending real-time data about their performance and condition. This allows you to take proactive measures before problems arise.

How does IIoT differ from IoT?

While the Internet of Things (IoT) focuses on consumer devices like smart home systems or wearables, the IIoT focuses on industrial applications. IIoT platforms are specifically designed for use in factories, production facilities, and other industrial settings. If IoT connects your kitchen appliances, then IIoT connects your production lines from Procom Automation, ensuring seamless and efficient manufacturing.

Why are IIoT platforms important in the industry?

IIoT platforms are the backbone of modern industry as they enable the automation and optimisation of production processes. With an IIoT platform like Clouver from Procom Automation, you gain access to real-time data analysis, predictive maintenance, and enhanced decision-making through data-driven insights. These advantages lead to higher productivity, lower operating costs, and more robust production.

What components make up an IIoT platform?

What are the key components of an IIoT platform?

An IIoT platform comprises several key components that work seamlessly together to achieve maximum efficiency. These include sensors, networks, data processing units, and analytical tools. These components work harmoniously to ensure you always have the information needed to make informed decisions.

What are the hardware and software components?

The hardware components of an IIoT platform include sensors and gateways. Sensors from Procom Automation accurately capture data from your machines, while gateways transmit this data to the central platform. On the software side, analytical tools and platforms like Clouver offer extensive functionalities for data processing, analysis, and visualisation. This combination of hardware and software ensures you have access to up-to-date and relevant information at all times.

What are some examples of IIoT platforms?

A standout example of an IIoT platform is Clouver from Procom Automation. Clouver is specifically designed to meet the needs of the manufacturing industry. With features like real-time monitoring, predictive maintenance, and comprehensive analytical tools, Clouver provides everything you need to optimise your production processes and stay competitive.

What does the technical infrastructure of an IIoT platform look like?

How does the Clouver Gateway work for data transfer?

The Clouver Gateway is an essential component of your IIoT platform. It collects data from your CNC machines and cutting machines from Procom Automation and securely transmits it to the cloud platform. This ensures that all relevant data is available in real-time, enabling you to respond immediately to changes.

What role do industrial communication protocols like EtherCAT play?

Industrial communication protocols like EtherCAT play a crucial role in the fast and reliable data transfer between your machines and the IIoT platform. EtherCAT enables high data transfer speeds and low latency, which are essential for real-time monitoring and control of your production processes.

Why are standardised interfaces like OPC UA important?

Standardised interfaces like OPC UA are indispensable for integrating various systems within your IIoT platform. OPC UA enables seamless communication between components, regardless of their manufacturer. This facilitates the expansion and adaptation of your IIoT platform without worrying about compatibility issues.

What is the significance of edge computing in IIoT platforms?

Edge computing is another important aspect of a modern IIoT platform. By processing data locally at the source, edge computing minimises latency and increases data processing efficiency. This is particularly useful for time-critical applications where quick decisions must be made based on the data.

How does data management and analysis work?

How are operational data captured and stored?

Capturing and storing operational data is the core of any IIoT platform. Sensors continuously capture data from your machines and transmit it to the cloud, where it is securely stored and made available for future analysis. With Clouver, you can ensure that all your operational data are effectively collected and stored, so you can access them at any time.

How is process information processed and analysed?

Processing and analysing process information allows you to identify patterns and anomalies in your production processes. Clouver offers advanced analytical tools that help you identify optimisation potentials and take proactive measures. This ensures that your production processes always run smoothly and efficiently.

What is predictive maintenance and how does it help you?

Predictive maintenance is one of the greatest strengths of IIoT platforms like Clouver. By analysing the collected data, you can plan maintenance work based on the actual conditions of your machines. This prevents unplanned downtime and extends the lifespan of your machines, saving costs in the long run and boosting productivity.

How does real-time monitoring and reporting work?

With real-time monitoring and reporting, you always have a precise overview of the condition of your machines and production processes. Clouver offers intuitive dashboards and user-friendly reports that help you respond to problems immediately and continuously make improvements. This keeps you one step ahead and allows you to react quickly to changes.

Where are IIoT platforms used?

How does an IIoT platform help with machine management and configuration?

IIoT platforms enable efficient management and configuration of your machines. With Clouver, you can quickly switch operating modes, adjust machine parameters, and monitor the performance of your CNC machines from Procom Automation. This leads to higher productivity while minimising downtime.

How does an IIoT platform support automated process control?

Automated process control optimises your production processes by automating repetitive tasks and minimising human error. Clouver allows you to implement control systems that intelligently manage your machines and continuously improve the efficiency of your production.

How does an IIoT platform improve quality control and assurance?

By continuously monitoring and analysing production data, you can identify and address quality issues early. Clouver helps maintain the quality of your products by providing precise data that you can use to optimise your production processes.

How does an IIoT platform support maintenance planning and execution?

Effective maintenance planning is crucial for the smooth operation of your production facilities. With Clouver, you can efficiently plan and execute maintenance work based on the real conditions of your machines. This extends the lifespan of your equipment while reducing downtime.

Clouver: Your IIoT Solution for Maximum Transparency!

Stay on top of every process in your manufacturing – from machine status to production data. Clouver enables you to make informed decisions based on reliable data. Request your free demo today!

How does integration and connectivity work?

How do you integrate an IIoT platform into existing systems?

An IIoT platform like Clouver offers comprehensive interfaces to your existing systems. This allows seamless integration and ensures that all your systems work together efficiently. This ensures that your production processes run without interruptions.

How does cloud connectivity and data transmission work?

Cloud connectivity is a key component of any modern IIoT platform. Clouver enables the secure and efficient transmission and storage of your data in the cloud. This ensures you have access to your operational data anytime and anywhere and can use it for analysis.

What external control options does an IIoT platform provide?

With external control options, you can monitor and control your machines and processes remotely. Clouver offers the flexibility to access your production facilities anytime and from anywhere, significantly enhancing your company's efficiency and responsiveness.

Why are standardised protocols important for integration?

The use of standardised protocols like OPC UA facilitates the integration and communication between different systems. Clouver relies on such protocols to ensure that all components of your IIoT platform work together seamlessly, achieving maximum efficiency.

What new developments and trends are there?

How does Clouver integrate artificial intelligence (AI) into IIoT platforms?

Integrating artificial intelligence into IIoT platforms like Clouver opens up entirely new possibilities. AI enables the analysis and prediction of machine behaviour, process optimisation, and the identification of patterns that may elude human analysts. This allows you to continuously improve your production processes and increase efficiency.

What advances are there in edge computing?

Advances in edge computing significantly improve data processing efficiency and speed. With Clouver, you can deploy edge devices to process data locally and transmit only the necessary information to the cloud. This reduces latency and increases the responsiveness of your IIoT platform.

How does Clouver protect your data from cyber-attacks?

Data security is a central issue in the implementation of IIoT platforms. Clouver from Procom Automation uses state-of-the-art security protocols, including encryption and firewalls, to protect your data from cyber-attacks. Regular security checks and updates ensure that your data is always safe.

What advantages does the integration of 5G offer for IIoT?

Integrating 5G technology into IIoT platforms like Clouver allows for faster and more reliable data transmissions. With 5G, you can further enhance the efficiency and performance of your production processes, as the high bandwidth and low latency enable almost instant data transmission.

How do you practically implement an IIoT platform?

What selection criteria are important for the right IIoT platform?

When choosing an IIoT platform, you should consider the specific requirements of your business. Think about which machines need to be connected, what functions you need, and how well the platform is compatible with your existing systems. Clouver from Procom Automation is an excellent choice as it is specifically tailored to the needs of the manufacturing industry.

What strategies help you with a successful implementation?

A successful implementation of an IIoT platform requires careful planning. Analyse your existing systems, select the right components, and thoroughly train your staff. With Clouver, you get not only a powerful platform but also the necessary support to ensure smooth implementation.

What are the best practices for using IIoT platforms?

To maximise the potential of your IIoT platform, you should continuously monitor and optimise. Use Clouver's analytical tools, implement strict security measures, and keep your systems up-to-date. These best practices help you work efficiently and securely and benefit from your IIoT platform in the long run.

How do you assess ROI and economic viability?

A cost-benefit analysis helps you evaluate the return on investment (ROI) of your IIoT platform. Consider the savings from reduced downtime, increased productivity, and optimised processes. With Clouver from Procom Automation, you can clearly quantify the benefits and ensure that your investment pays off quickly.

What challenges are there and how do you solve them?

How do you protect your data from cyber-attacks?

Data security is one of the biggest challenges in implementing IIoT platforms. With Clouver from Procom Automation, you are well-protected. By using state-of-the-art encryption technologies, firewalls, and regular security checks, you can effectively protect your data from cyber-attacks.

How do you integrate IIoT into existing systems and processes?

Integrating into existing systems can be complex, but Clouver makes this process significantly easier. Thanks to standardised protocols like OPC UA and a flexible architecture, you can seamlessly integrate your existing systems and continue your production processes without interruptions.

How do you scale your IIoT platform?

A scalable IIoT platform allows you to adjust your solution to the growing demands of your business. Clouver from Procom Automation is designed to grow with your business, enabling you to integrate additional machines and processes as demand increases.

How do you effectively train your staff?

Training and further education of your staff is crucial for fully leveraging the benefits of the IIoT platform. Procom Automation offers comprehensive training programs and support to ensure your team is well-prepared to utilise Clouver's potential optimally.

Conclusion

An IIoT platform is a crucial tool for modern industry, enabling the networking and automation of machines and processes. With a platform like Clouver from Procom Automation, you can collect, analyse, and use data to significantly increase the efficiency and productivity of your business. Key features of an IIoT platform include real-time data collection, predictive maintenance, and process optimisation.

Procom Automation offers a powerful IIoT platform with Clouver tailored specifically to the needs of the manufacturing industry. If you want to learn more about the opportunities of IIoT technology, visit our post or book a demo version of Clouver. Discover how Procom Automation can elevate your production processes to the next level!

Sergej Gigel

Senior Sales Manager

Have questions about the topic or want to learn more about our solutions?

Contact us and discover how our products can future-proof your machines. Let’s work together to find out how we can help take your production to the next level!

- +49 241 93681-500

- contact@procom-automation.de