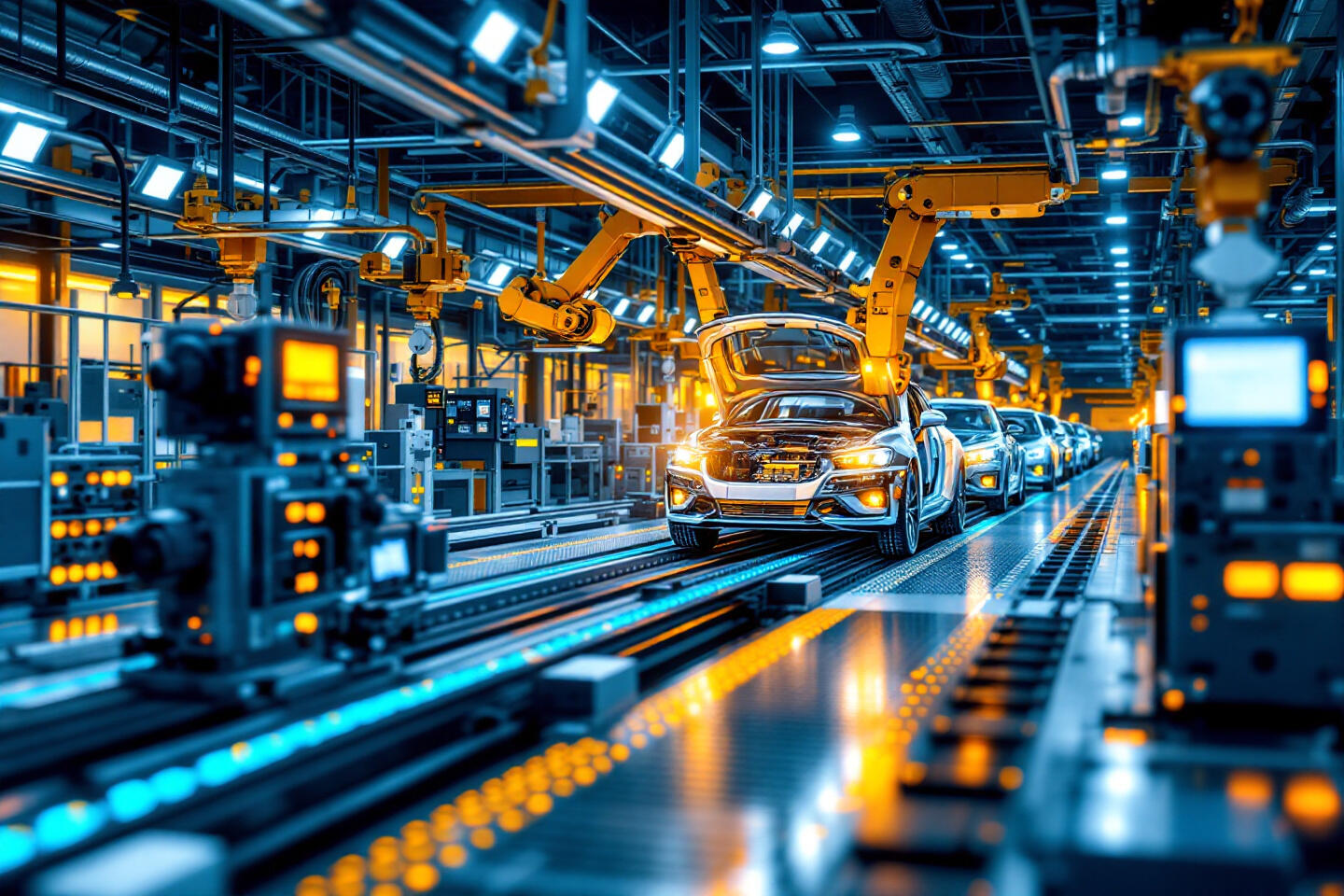

Why is OEE Important for You?

In today's highly competitive manufacturing landscape, maximising production performance is crucial for success. This is where Overall Equipment Effectiveness (OEE) comes into play – an indispensable tool for measuring and optimising the efficiency of your production equipment. But what exactly is behind this term, and why is it so relevant for modern production operations?

In this post, we dive deep into the topic of OEE and answer central questions that many production managers and engineers have: How is OEE calculated? What are the typical sources of error? And how can implementing OEE in your operation not only increase productivity but also minimise unplanned downtime?

What is OEE and Why Is It Important?

Definition and Significance of OEE

Overall Equipment Effectiveness (OEE) is a comprehensive metric that measures the productivity and efficiency of your production equipment. It consists of three main components: availability, performance, and quality. With OEE, you can precisely identify how well your machines and equipment are being utilised and where exactly there are potential improvements. This metric is essential for identifying bottlenecks in the production process and taking targeted measures to increase efficiency.

Historical Development and Origin

OEE was originally developed by Seiichi Nakajima as part of the Total Productive Maintenance (TPM) concept. Nakajima recognised the need for a unified metric that covers all aspects of equipment performance. Since then, OEE has evolved into an international standard in the manufacturing industry. Companies worldwide use OEE to evaluate the performance of their machines and drive continuous improvements.

Why OEE Is Important for the Manufacturing Industry

OEE is indispensable because it provides a holistic view of the efficiency of your production equipment. By analysing availability, performance, and quality, you can understand the reasons for production losses in detail. A high OEE value indicates that your production equipment is being used efficiently, leading to higher productivity and lower costs. With OEE, you can take targeted measures to maximise the utilisation of your machines and increase your company's competitiveness.

How Is OEE Composed?

Availability: How Often Are Your Machines Operational?

Availability measures the time during which your equipment is actually producing, relative to the planned production time. It shows how often your machines are operational. The calculation formula is: Availability = (Operating Time / Planned Production Time) x 100%. Planned and unplanned downtime significantly affect availability. This includes maintenance work, machine failures, or setup times. Precise documentation and analysis of these downtimes are critical to maximising availability.

Performance: How Efficiently Are Your Machines Operating?

Performance measures the actual production speed relative to the maximum possible speed of your equipment. It shows how efficiently your machines are operating. The calculation formula is: Performance = (Actual Production Quantity / Theoretical Maximum Production Quantity) x 100%. Slow cycle times, small stops that impact production speed, and inefficient workflows can reduce performance. By optimising these factors, you can significantly increase the production rate.

Quality: How Good Are Your Products?

Quality measures the proportion of defect-free products in total production volume. It is an indicator of how well your production processes meet the desired quality standards. The calculation formula is: Quality = (Number of Defect-free Products / Total Production Quantity) x 100%. Defective products, rework, and scrap reduce quality. Strict quality control and continuous improvement measures are necessary to enhance quality and reduce costs associated with scrap.

How Do You Calculate OEE?

Detailed Calculation Formulas for All Components

The OEE calculation integrates the three components of availability, performance, and quality into a single metric: OEE = Availability x Performance x Quality. This formula allows you to gain a clear overview of the overall performance of your production equipment and plan targeted optimisation measures.

Industry-Specific Benchmarks and Target Values

The target values for OEE vary depending on the industry and production environment. In the automotive industry, an OEE value of 85% is often considered "world-class," while in other sectors, values below 60% may indicate significant improvement potential. It is important to know industry-specific benchmarks to realistically assess your company's performance.

Typical Sources of Error in OEE Calculation

Common sources of error in OEE calculation include inaccurate data collection, misunderstandings regarding the definition of downtime, and neglecting quality losses. Accurate and consistent data collection is crucial for reliable OEE values. With the right software, such as "Clouver" from ProCom Automation, you can minimise these sources of error and obtain accurate data for your analyses.

Make Your Machine Fleet Future-Ready!

Clouver helps you connect machines in real time and identify hidden optimisation opportunities. Our platform reduces downtime and streamlines workflows. Contact us now for a no-obligation consultation and take your production to the next level!

How Do You Implement and Optimise OEE?

Step-by-Step Guide to OEE Implementation

Start by recording operating times, production quantities, and quality data. Use "Clouver," the leading Industrial Internet of Things platform from ProCom Automation, to capture real-time data. Calculate OEE using the detailed formulas for calculating availability, performance, and quality. Analyse the main causes of losses in the three OEE components and use the analysis functions of "Clouver" to identify weaknesses. Develop strategies to improve identified weaknesses, e.g., by optimising maintenance schedules or training employees. Implement a continuous monitoring system with "Clouver" to track progress and make further optimisations.

Change Management in OEE Projects

A successful OEE project requires effective change management. Ensure that all employees accept and support the changes. Communicate clearly the benefits of OEE and actively involve the team in the improvement process. With the support of "Clouver," you can increase acceptance and ensure a smooth transition.

Employee Training and Involvement

Train your employees on the importance and application of OEE. They should understand the objectives and methods and actively contribute to improvements. Regular training sessions and workshops foster understanding and motivation to achieve OEE goals.

Continuous Improvement Process (CIP)

Implement a continuous improvement process to regularly monitor and continuously enhance OEE values. With "Clouver," you can identify trends and take proactive measures to steadily increase the efficiency of your production equipment.

How Does Digitalisation and Industry 4.0 Support OEE?

Automated OEE Data Collection

Integrate Industrial Internet of Things sensors for real-time data collection and monitoring. With "Clouver SmartKit" from ProCom Automation, you can automatically capture and analyse OEE data, providing you with always up-to-date and precise information.

Machine Learning for OEE Optimisation

Implement machine learning algorithms to predict machine downtimes and optimise production parameters. These technologies enable you to proactively respond to potential issues and continuously improve production performance.

Predictive Maintenance Based on OEE Data

Use OEE data for planning predictive maintenance measures. This minimises unplanned downtime and increases machine availability. With "Clouver Paperless," you can efficiently design maintenance schedules and extend the lifespan of your equipment.

Integration into Existing MES and ERP Systems

Integrate OEE data into your existing Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP) systems. This provides a holistic view of your production processes, allowing you to make informed decisions. "Clouver" offers seamless integration capabilities to efficiently connect and use your data.

Practical Application of OEE

Case Studies from Different Industry Sectors

Study successful OEE implementations in similar industries to adopt best practices. For example, an automotive manufacturer has increased machine availability by 20% and significantly improved production speed through the use of OEE and "Clouver."

ROI Calculation for OEE Improvement Projects

Calculate the return on investment (ROI) for OEE improvement projects to evaluate their economic viability. Analyse the costs of implementing "Clouver" and the expected savings from increased efficiency and reduced downtime.

Troubleshooting Guides

Create troubleshooting guides to address typical issues in OEE implementation. These guides offer practical solutions and tips for quickly and effectively overcoming challenges.

Best Practices for Various Production Environments

Use best practices to optimise OEE in various production environments. Whether in small-batch production or complex production lines, tailor your OEE strategies to the specific requirements and leverage the expertise of ProCom Automation.

Conclusion: Your Path to More Efficient Production

Overall Equipment Effectiveness (OEE) is a crucial indicator for measuring the efficiency and productivity of production equipment. By analysing the availability, performance, and quality of your machines, OEE provides valuable insights that help in early identification of bottlenecks and minimisation of downtime. With "Clouver," our powerful Industrial Internet of Things platform from ProCom Automation, you can monitor and analyse these parameters in real time. This not only enables proactive maintenance and resource optimisation but also significantly increases the overall productivity of your production.

Would you like to learn more about the benefits of "Clouver" and how it can revolutionise your production? Visit our blog for more in-depth content or book a demo version of "Clouver" to experience the platform firsthand. Contact us today for a non-binding consultation and discover how ProCom Automation can support you!

Sergej Gigel

Senior Sales Manager

Have questions about the topic or want to learn more about our solutions?

Contact us and discover how our products can future-proof your machines. Let’s work together to find out how we can help take your production to the next level!

- +49 241 93681-500

- contact@procom-automation.de