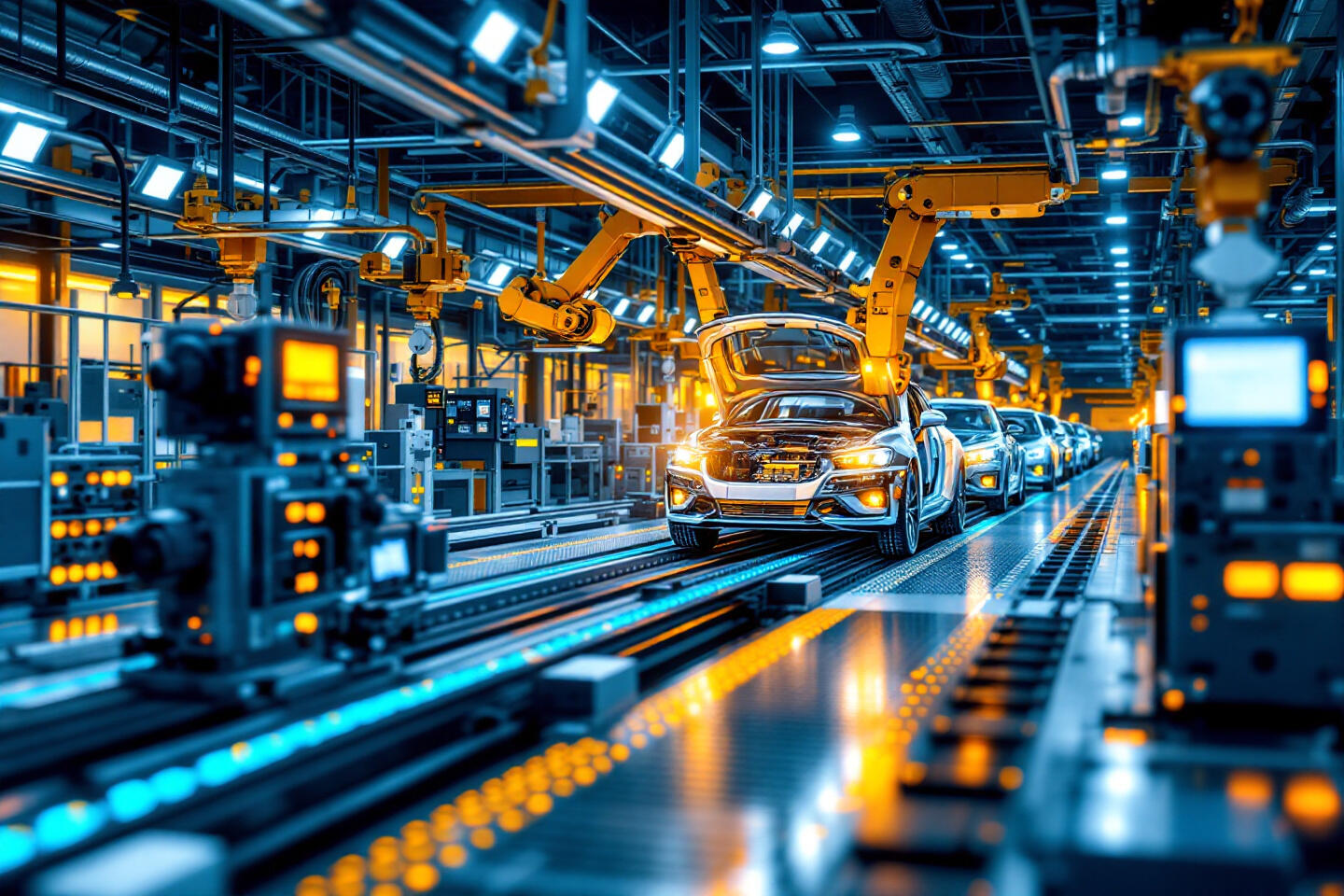

Introduction: Why is the Industrial Internet of Things so important?

In today's era, where digitalisation is revolutionising the industrial world, you may be facing the challenge of making your production processes more efficient, safer and more cost-effective. This is where the Industrial Internet of Things comes into play – a technology that networks machines, sensors and systems together to capture and analyse data in real time. Read on to learn how the Industrial Internet of Things can transform your industrial processes and what benefits it offers for your company.

What is the Industrial Internet of Things?

What distinguishes the Industrial Internet of Things from Consumer IoT?

The Industrial Internet of Things refers to the networking of machines, sensors and other devices in industrial environments to collect, exchange and analyse data. Whilst Consumer IoT aims to network everyday devices such as smartphones and household appliances, the Industrial Internet of Things focuses on industrial applications. These systems are more robust and secure, specifically designed for demanding environments. You benefit from the Industrial Internet of Things by receiving precise and reliable data specifically tailored to industry requirements.

Why is the Industrial Internet of Things so relevant in modern industry?

The Industrial Internet of Things plays a crucial role in modern industry because it enables you to optimise your production processes, increase efficiency and reduce operating costs. Through real-time monitoring and analysis of production data, you can respond more quickly to changes and make informed decisions. This leads to higher product quality, better resource utilisation and an overall more competitive position in the market.

How has the Industrial Internet of Things evolved?

The development of the Industrial Internet of Things is closely linked to advances in sensor and network technology as well as data analysis. In the early 2000s, companies began integrating their first networked devices into their production lines. With the introduction of cost-effective sensors and powerful cloud platforms, the Industrial Internet of Things has evolved into a key technology for Industry 4.0. Advances in artificial intelligence and machine learning have further expanded the possibilities of the Industrial Internet of Things, making complex analyses and predictive maintenance now feasible.

What technical components are necessary for the Industrial Internet of Things?

What role do sensors play in data collection?

Sensors are the eyes and ears of the Industrial Internet of Things. They capture physical parameters such as temperature, pressure, humidity and vibrations and convert these into digital data. This data forms the basis for analysing and optimising your production processes. High-precision sensors from ProCom Automation ensure that you always receive accurate and reliable data enabling informed decision-making.

How do gateways function in data transmission?

Gateways act as a bridge between the sensors and the cloud. They collect the data captured by the sensors, filter and process it, and then securely transmit it to the cloud platform for further analysis. Gateways from ProCom Automation are designed to efficiently manage large volumes of data and ensure stable connectivity, even in demanding industrial environments.

Why are cloud platforms important for the Industrial Internet of Things?

Cloud platforms provide the necessary infrastructure for storing and analysing large volumes of data. They enable you to process data in real time, recognise patterns and make informed decisions. With ProCom Automation's Industrial Internet of Things software Clouver, you receive a powerful solution that not only stores data but also provides intelligent analyses and dashboards to maintain oversight of your production processes.

What significance do standardisation and protocols like OPC UA have?

Standardised protocols such as OPC UA (Open Platform Communications Unified Architecture) are crucial for the smooth exchange of data between different Industrial Internet of Things components. They ensure the interoperability and compatibility of devices and systems from different manufacturers. By implementing OPC UA in your Industrial Internet of Things systems, you ensure seamless communication and integration, significantly increasing the efficiency and reliability of your production processes.

Where is the Industrial Internet of Things applied?

How does Predictive Maintenance help in forecasting and preventing failures?

Predictive Maintenance uses Industrial Internet of Things data to monitor the condition of machines in real time and identify potential problems early. Through predictive maintenance, you can minimise unplanned downtime and extend machine lifespans. ProCom Automation's Clouver software continuously analyses data from your CNC machines and cutting machines to precisely predict maintenance requirements and take proactive measures.

How does the Industrial Internet of Things contribute to production optimisation?

Industrial Internet of Things enables continuous monitoring and analysis of production processes. By identifying bottlenecks and inefficiencies, you can optimise your production workflows and increase efficiency. With Clouver, you can monitor the performance of your ProCom Automation CNC machines and cutting machines in precise detail to implement targeted improvements and sustainably increase productivity.

How does the Industrial Internet of Things improve quality assurance?

Industrial Internet of Things data can be used to monitor product quality in real time. Through early detection of quality issues, you can respond quickly and take measures to improve product quality. Clouver from ProCom Automation continuously analyses production data to detect deviations and ensure that your CNC machines and cutting machines consistently deliver optimal quality.

How does the Industrial Internet of Things optimise energy consumption?

Industrial Internet of Things helps you monitor and optimise energy consumption. By analysing energy data, you can identify inefficient processes and take measures to reduce energy consumption. With ProCom Automation's Clouver software, you can precisely monitor the energy consumption of your production facilities and specifically utilise optimisation potential to reduce costs and produce more sustainably.

What technical infrastructure does the Industrial Internet of Things require?

What is Edge Computing and how does it help with data processing?

Edge Computing enables data processing close to the source, directly at the machines and devices. This reduces latency times and relieves the network infrastructure, as only relevant data is transmitted to the cloud. ProCom Automation offers Edge Computing solutions that enable rapid data processing and immediate responses to production events, further increasing the efficiency of your CNC machines and cutting machines.

What advantages and challenges does cloud integration offer?

The integration of Industrial Internet of Things data into cloud platforms offers numerous advantages, including scalability, flexibility and cost efficiency. However, you must also overcome challenges such as data security and data protection. With ProCom Automation's Clouver software, you benefit from secure cloud integrations that protect your production data whilst providing flexible analysis and scaling options.

How do you choose the right network topology for your Industrial Internet of Things network?

Choosing the right network topology is crucial for the performance and reliability of Industrial Internet of Things systems. Companies must consider various topologies such as star, tree or mesh networks and weigh their advantages and disadvantages. ProCom Automation supports you in selecting and implementing the optimal network topology for your CNC machines and cutting machines to ensure stable and efficient data communication.

How do you protect your Industrial Internet of Things system from cyber attacks and data loss?

A robust security architecture is essential to protect Industrial Internet of Things systems from cyber attacks and data loss. You should implement security concepts and best practices to secure your Industrial Internet of Things infrastructure. Clouver from ProCom Automation offers comprehensive security features that protect your data and systems and ensure that your CNC machines and cutting machines are protected against unauthorised access and data loss.

Secure Your Production Processes with Clouver!

Discover how our IIoT platform reveals untapped potential and sustainably boosts efficiency. Real-time data analysis helps you minimise errors, reduce costs, and maximise productivity. Get started with a no-obligation consultation today – together, we'll find the best solution for your business!

How do you implement the Industrial Internet of Things in practice?

How do you proceed with the step-by-step integration of the Industrial Internet of Things?

The step-by-step integration of Industrial Internet of Things into existing systems requires careful planning and implementation. Define clear objectives and requirements, select suitable sensors and hardware, and conduct a pilot installation to analyse and optimise results. ProCom Automation supports you in finding the best solutions for your CNC machines and cutting machines and ensuring smooth implementation of the Clouver software. Begin with a limited number of machines, monitor performance and gradually expand the integration to minimise risks and ensure long-term success.

What best practices should you observe when implementing the Industrial Internet of Things?

Success factors for implementing Industrial Internet of Things include close collaboration between IT and OT teams, staff training, and continuous monitoring and optimisation of Industrial Internet of Things systems. Ensure your teams at ProCom Automation communicate well with each other and work together on optimising your CNC machines and cutting machines. Invest in regular training to ensure your staff can fully exploit the benefits of Clouver, and continuously monitor system performance to make adjustments and improvements.

What typical challenges are there in implementing the Industrial Internet of Things and how do you solve them?

Typical challenges in implementing Industrial Internet of Things include integrating existing systems, high initial investments and ensuring data security. ProCom Automation helps you proactively address these challenges by providing customised solutions for integrating your CNC machines and cutting machines, offering cost-effective options for implementing Clouver, and implementing comprehensive security measures to protect your data.

How do you calculate the ROI for Industrial Internet of Things projects?

Calculating the Return on Investment (ROI) for Industrial Internet of Things projects is crucial to assess the economic benefits. Analyse the potential savings through increased efficiency, reduced downtime and optimised energy consumption compared to investment costs. With Clouver from ProCom Automation, you can collect and analyse precise data to calculate the ROI of your Industrial Internet of Things initiatives and make informed decisions for future investments.

What future perspectives does the Industrial Internet of Things offer?

How is Artificial Intelligence used in the Industrial Internet of Things?

Artificial Intelligence (AI) plays an increasingly important role in the Industrial Internet of Things. By using AI, you can further automate processes and develop intelligent systems that make independent decisions and implement optimisations. Clouver from ProCom Automation integrates AI functions that enable you to recognise complex patterns in your production data and take proactive measures for process improvement.

What advantages does 5G integration offer in the Industrial Internet of Things?

The integration of 5G into Industrial Internet of Things systems offers improved connectivity and higher speeds. This enables real-time transmission of large volumes of data and opens up new areas of application for the Industrial Internet of Things. ProCom Automation supports the implementation of 5G technologies in your CNC machines and cutting machines, ensuring faster and more reliable data communication and allowing you to benefit from the advantages of the latest network technologies.

What are Digital Twin concepts and how do they help in the Industrial Internet of Things?

A Digital Twin is a virtual model of a physical object or system. It is used to simulate and analyse the behaviour and performance of the real object. In the Industrial Internet of Things context, the Digital Twin helps optimise processes and develop maintenance strategies. With Clouver from ProCom Automation, you can create Digital Twins of your CNC machines and cutting machines to monitor their performance, conduct simulations and implement proactive optimisations.

Conclusion: How can you utilise the Industrial Internet of Things?

The Industrial Internet of Things revolutionises industrial production by networking machines, sensors and systems together, thus enabling comprehensive monitoring and analysis of production data. Through real-time monitoring and analysis of key performance indicators such as OEE and MTTR, you can increase machine availability, optimise throughput and minimise unplanned downtime. Platforms like Clouver from ProCom Automation offer a modular solution that collects data from various sources and visualises this on user-friendly dashboards to identify bottlenecks early and sustainably increase overall productivity.

Interested in further information or in how Clouver can help you optimise your production processes? Visit our article for further content or book a demo version of Clouver to experience the benefits of the Industrial Internet of Things platform yourself. Click here to learn more!

Sergej Gigel

Senior Sales Manager

Have questions about the topic or want to learn more about our solutions?

Contact us and discover how our products can future-proof your machines. Let’s work together to find out how we can help take your production to the next level!

- +49 241 93681-500

- contact@procom-automation.de