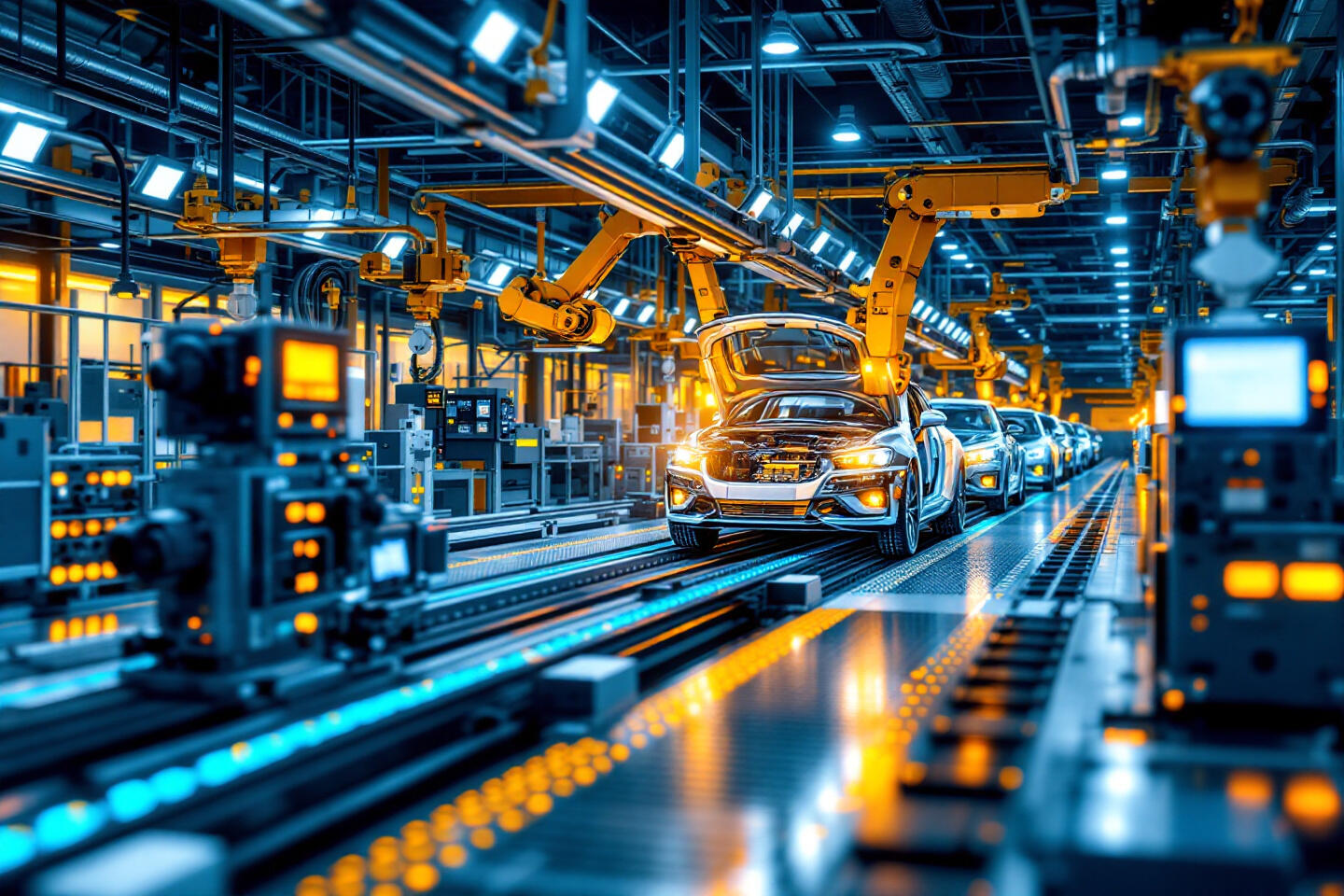

Challenges in Modern Industry

In today's fast-paced and technologically advanced world, many companies face the challenge of making their production processes more efficient and cost-effective. Automation and control systems play a critical role in this endeavour. They not only enable higher efficiency and productivity but also enhance quality and safety in production. But how can you optimally use these systems to streamline your production processes?

What Are Automation and Control Systems?

Definition and Importance

Automation and control systems are technologies and software solutions that control and automate industrial processes and machinery. These systems include various components such as control architectures (e.g., CNC and PLC), interfaces (e.g., OPC UA and EtherCAT), sensors, actuators, and human-machine interfaces (HMI). They are essential for making production processes efficient, reducing error rates, and maintaining consistently high production quality.

Historical Development

The development began with simple mechanical controls and has evolved into highly complex digital solutions. The introduction of programmable logic controllers (PLC) and computer numerical control (CNC) has significantly enhanced flexibility and precision. Modern systems integrate advanced technologies such as the Industrial Internet of Things, artificial intelligence, and machine learning to further optimise processes and enable predictive maintenance.

Where Are Automation and Control Systems Used?

Automation and control systems are used in almost all industrial sectors. In the automotive industry, they control assembly and production lines, improve quality control, and increase production efficiency. In food production, they ensure hygiene and consistency in manufacturing, control packaging machines, and automate process steps. In the chemical industry, they monitor and control complex chemical reactions and production processes. In the pharmaceutical industry, they ensure precise dosing and quality control in the manufacturing of medications.

What Components Are Included in Automation and Control Systems?

Understanding Control Architecture

The control architecture forms the heart of every automation and control system. Two main types are particularly relevant: CNC (Computer Numerical Control) and PLC (Programmable Logic Controller). CNC systems control machine tools through precise, programmed instructions and are indispensable in metalworking, woodworking, and the manufacturing of complex components. PLC systems are flexible and can be used for a variety of control tasks in the industry.

Setting Up Interfaces

Interfaces are crucial for communication between the various components of an automation system. OPC UA (Open Platform Communications Unified Architecture) is a standardised interface that enables communication between different system components. EtherCAT (Ethernet for Control Automation Technology) is a real-time Ethernet protocol that is particularly suited for automation technology, offering high data transfer rates and low latency.

Sensors and Actuators

Sensors measure physical quantities such as temperature, pressure, or position and continuously provide data on the status of machines and processes. Actuators convert this information into mechanical movements or other actions, thus effecting the actual control of production processes.

Human-Machine Interfaces (HMI)

HMIs enable interaction between the operator and the machine. Modern HMIs often offer touchscreens or other user-friendly input devices that allow intuitive operation and monitoring of production processes. This increases the efficiency and user-friendliness of your systems.

Your Path to More Efficient Cutting Processes Starts Here!

With ProCom's control solutions, you save time, material, and energy. Benefit from our expertise in automation and digitisation. Contact us now to learn more!

How Do Automation and Control Systems Help in Practice?

Optimising Waterjet Cutting

In the area of waterjet cutting, automation and control systems offer significant advantages. Systems can control multiple cutting heads simultaneously, increasing flexibility and efficiency. Manual adjustment of the abrasive amount and pressure allows flexible adaptation to different materials and requirements, improving cutting quality. The CNC machines from ProCom Automation are leaders in this field, offering precise control and high adaptability.

Improving Machine Tool Control

Automation and control systems optimise the precision and efficiency of machine tools. By accurately controlling movements and automating repetitive tasks, you can increase production speed while improving accuracy.

Process Automation and Quality Control

These systems control and monitor complex industrial processes to ensure consistency and quality. They enable real-time process adjustments and quicker responses to changes, thereby increasing overall productivity. Automated systems can continuously collect and analyse quality data to ensure that products meet required standards. This reduces scrap and rework and increases customer satisfaction.

What Intelligent Functions Do Automation and Control Systems Offer?

Automatic Height Control

This function allows real-time adjustment of the cutting height to compensate for material irregularities, ensuring consistent cutting quality even with varying material thicknesses.

Adaptive Cutting

Adaptive cutting automatically adjusts cutting parameters to maximise efficiency and quality. This leads to optimised processes and less material waste.

Predictive Maintenance

With predictive maintenance, you can schedule maintenance intervals and minimise downtime by using operating hours counters and wear part management. This ensures higher machine availability and reduces unexpected failures.

Data Collection and Analysis

The continuous monitoring and analysis of real-time data enable process optimisation. Targeted data analysis allows you to identify inefficient areas and implement improvements effectively.

What Are the New Developments and Trends?

Industry 4.0 Integration

The integration of Industry 4.0 is revolutionising manufacturing by connecting machines and systems. Key aspects include cloud connectivity (e.g., Clouver Gateway), transmitting machine data to the cloud for remote monitoring and analysis with the best production monitoring software Clouver, digital twins, IoT connectivity, and real-time data processing.

Artificial Intelligence (AI) and Machine Learning

AI and machine learning significantly contribute to the improvement of automation and control systems. They enable process optimisation, quality prediction, automatic parameter adjustment, and anomaly detection, resulting in more efficient and reliable production.

How Can You Practically Use Automation and Control Systems?

Operating Modes and Configuration

Managing different operating modes is crucial for smooth production operations. ProCom Automation's machine manager simplifies the management and configuration of these operating modes. With the machine manager, you can quickly switch between operating modes, adjust machine parameters, and ensure that your production processes run optimally at all times.

Maintenance and Upkeep

Effective maintenance and upkeep are essential for extending the lifespan of your machines and minimising unplanned downtime. Operating hours counters track the operating hours of machines to plan maintenance work in a timely manner. Wear part management monitors the condition of wear parts and replaces them promptly. Maintenance planning based on operating data ensures efficient maintenance work. With ProCom Automation's software, problems can be quickly identified and resolved.

What Economic Aspects Are Important?

Automation and control systems offer numerous economic benefits. An ROI (Return on Investment) analysis often shows a rapid payback through increased efficiency and reduced operating costs. Optimising energy consumption lowers production costs and contributes to sustainability. Higher productivity through automated processes enables faster time-to-market and greater market share. Cost-saving potentials are identified and utilised through optimised processes and reduced material consumption.

Conclusion

Automation and control systems are essential for the efficiency and precision of modern manufacturing processes. In this post, we have highlighted the various functions and benefits of ProCom Automation's systems. These include support for pure water cutting with up to nine cutting heads, flexible adjustment of abrasive and pressure amounts, and automatic height control to compensate for material irregularities. The integration of operating modes, marking and punching functions, and the capability to transfer machine data to the Clouver cloud platform round off the powerful profile of these systems.

Do you want to learn more about ProCom Automation's automation and control systems or book a demo version of Clouver? Visit our website to discover more exciting content or contact us directly to discuss your specific requirements. Let's work together to increase the efficiency of your production processes!

Sergej Gigel

Senior Sales Manager

Have questions about the topic or want to learn more about our solutions?

Contact us and discover how our products can future-proof your machines. Let’s work together to find out how we can help take your production to the next level!

- +49 241 93681-500

- contact@procom-automation.de